Casing capping wiring

Casing Capping is one of the oldest wiring systems and has been very popular and frequently used. This post will discuss what is Casing Capping Wiring, its installation procedure, types of joints, 2 way and 3 way design, advantages and disadvantages, casing capping wiring. Casing capping wiring process of connecting different accessories for distributing electrical energy from supplier to home appliances such as lamps, fans and other domestic appliances is known as Electrical Wiring. It is one of the simplest forms of electric wiring systems.

Join TheConstructor to ask questions, answer questions, write articles, and connect with other people. When you join you get additional benefits. By registering, you agree to the Terms of Service and Privacy Policy. Lost your password? Please enter your email address. You will receive a link and will create a new password via email. Sorry, you do not have permission to ask a question, You must log in to ask a question.

Casing capping wiring

Casing Capping Wiring- Installation means the act of installing something. Connecting two things or recombining two things in such a specific configuration or sequence that a complete system builds as a result of their joining or conjugation, is called installation. Electrical installation means the provision of corresponding supply to electrical appliances or instruments and their induction together with the safety circuits. The electrical installation provides a safe source for connecting electrical appliances of a consumer with electrical supply through over current and earth leakage protection. It consists of all cables, pertinent safety components, and control gear. In short, fixing different types of circuits and electrical equipment on a panel, recombination of electrical components with an incomplete system for making a complete system thereof, installation of electrical wiring in a precise or correct fashion either temporarily or permanently, installation of protective gadgets, installation of service lines on a one floor or multi-floor buildings, installation of motors, installation of load and earthing system are all included in electrical installation. In fact, the electrical installation consists of a complete system of all types of electrical wiring and its associated electrical components or instruments, protection, testing, signal communication circuits, and entire instruments related to the electrical control, installed in residential and commercial buildings, industrial units, factories, and refineries, etc. Conduit wiring may further be classified into the following two types. This type of wiring system once used to be very popular. However, now it has been replaced by the conduit wiring system. Although this wiring system is quite ancient, however, it is still being used in offices, homes, shops, and other ordinary premises. There are the following two types of casing capping wiring systems. Wooden Casing Capping Wiring. This rectangular type wide clamp, wherein grooves are being molded, is called casing. The casing is installed on the wall with the help of dowel pins or rowel plugs.

However, you must choose a certain design of trunk casing and capping based on your needs.

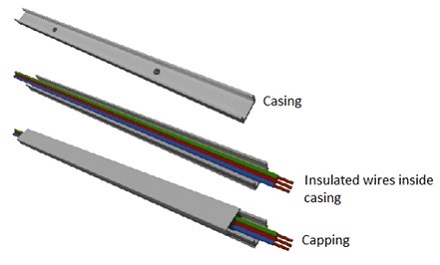

Despite being one of the oldest methods of wiring, casing capping is still used extensively today. This form of wiring is one of the most fundamental. Putting PVC-insulated wire in a plastic container and then capping the whole thing is what is meant by the term "casing capping. Wires are routed via grooves in a rectangular strip that serves as the casing. Casing capping is a fundamental sort of electric wire arrangement. Various shapes and sizes of moulded domes are utilised to cover the wires.

One of the oldest and most commonly seen wiring in use today is casing capping wiring. PVC-insulated wires are encased in plastic casings and protected with a cap in this approach to electrical wiring. The casing capping wiring is generally recommended for low-voltage wiring in homes, offices, and devices, as well as for wire distribution and protection. The casing is typically a rectangular strip with a grey or white channel and cap. It comes in sizes of 1. The system has a year lifespan and performs admirably in homes and offices. PVC casing and capping is a fantastic product that has many uses in wiring installations.

Casing capping wiring

The electrical wiring in which casing and capping are used is known as the casing and capping wiring system. Plastic casing and cap are used in this wiring system, hence called casing and capping wiring system. The case is a strip-like rectangular portion where the PVC insulated wires or the cables are placed. The case has grooves in it and the cables are run through them. The cap is used to cover the cables. This is one of the simplest and oldest wiring systems. But it has not lost its popularity.

Where does crazy pieces live

PVC casing and capping shall be of good quality PVC, free from defects like deformation, unevenness, blisters, cavities, etc. For telephone cable management, a typical casing and capping wiring system type that offers lots of customisation is called grilled fit. As a result of capping, such type of wiring remains protected against moisture, sunlight, smoke, dirt, and dust. Close Search for. Conduit wiring may further be classified into the following two types. It is not affected by moisture or water. This method involves a lot of labor. PVC has the highest level of chemical resistance available, making it the most durable material on the market. The sizes being generally used are 25 mm, 38 mm, and 51 mm. Despite being one of the oldest methods of wiring, casing capping is still used extensively today.

In this wiring system VIR wire or PVC wires run in the grooves of the teak wood casing and capping that is why this system is known as casing and capping system of wiring. The casing is first fixed on the surface of wall or ceiling by means of wooden gitties and wood screws.

Next article. Your Query. Do you need to remove the ads? This type of wiring is not suitable for places having moisture or in open areas, because its casing is damaged through water and moisture etc. Moreover, it also has no danger of worm-eating by white ants. As PVC capping does not require screws to be fitted on the casing, therefore this type of capping can easily be removed or fitted again as and when required. Its installation is pretty easy. In short, fixing different types of circuits and electrical equipment on a panel, recombination of electrical components with an incomplete system for making a complete system thereof, installation of electrical wiring in a precise or correct fashion either temporarily or permanently, installation of protective gadgets, installation of service lines on a one floor or multi-floor buildings, installation of motors, installation of load and earthing system are all included in electrical installation. It is one of the simplest forms of electric wiring systems. Connecting two things or recombining two things in such a specific configuration or sequence that a complete system builds as a result of their joining or conjugation, is called installation. As a result, we'll cover this procedure in more detail in the section on different types of casing and capping wire. By registering, you agree to the Terms of Service and Privacy Policy. However, you must choose a certain design of trunk casing and capping based on your needs.

It agree, your idea is brilliant

You are not right. I suggest it to discuss. Write to me in PM.

What amusing topic