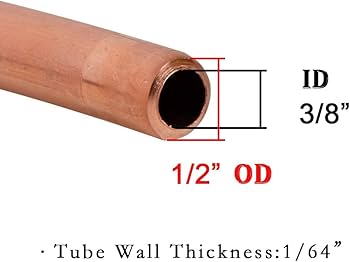

Copper tubing wall thickness

Copper tubing wall thickness K is a thick walled, flexible copper tubing - much thicker walls than Type L and M. Type K is required new gridania underground installations and is used for water services, plumbing, heating, steam, gas and oxygen, oil and other applications where thick walled tubes are required. Type K copper tubing can be used with sweat, flared and compression fittings.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. The content in this website may be used but with no warranty or liability. These copper tubing sizes and dimensions are believed to be correct but should always be double checked with alternative sources. Strictly adhere to and follow all applicable national and local regulations and practices.

Copper tubing wall thickness

Copper tubing is most often used for heating systems and as a refrigerant line in HVAC systems. Copper tubing is slowly being replaced by PEX tubing in hot and cold water applications. There are two basic types of copper tubing, soft copper and rigid copper. Copper tubing is joined using flare connection, compression connection, pressed connection, or solder. Copper offers a high level of corrosion resistance but is becoming very costly. Soft or ductile copper tubing can be bent easily to travel around obstacles in the path of the tubing. While the work hardening of the drawing process used to size the tubing makes the copper hard or rigid, it is carefully annealed to make it soft again; it is, therefore, more expensive to produce than non-annealed, rigid copper tubing. It can be joined by any of the three methods used for rigid copper, and it is the only type of copper tubing suitable for flare connections. Soft copper is the most popular choice for refrigerant lines in split-system air conditioners and heat pumps. Rigid copper is a popular choice for water lines. Rigid or "Hard" copper tubing is generally referred to as "pipe". Copper "piping" is referred to by nominal pipe size, or the inner diameter. Rigid copper, rigid due to the work hardening of the drawing process, cannot be bent and must use elbow fittings to go around corners or around obstacles.

Lifting Bags and Pipe Handlers. Type K copper tubing can be used with sweat, flared and compression fittings. Often referred to as a metal framing system, this product line utilizes strut channel in conjunction with a variety of channel fittings and channel clamps.

Products in this category are used in the supporting of pipe for typical commercial, industrial, and fire protection applications. Pipe supports are designed to anchor, guide, absorb shock, and support a specified load. Often referred to as a metal framing system, this product line utilizes strut channel in conjunction with a variety of channel fittings and channel clamps. These products provide contractors with a flexible supporting system for pipe and conduit across all plumbing and mechanical applications. Taylor Pipe Supports and the Walraven Group are excited to announce the formation of our Canadian partnership. This section of our website highlights the Walraven products now stocked in Canada.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. The content in this website may be used but with no warranty or liability. These copper tubing sizes and dimensions are believed to be correct but should always be double checked with alternative sources. Strictly adhere to and follow all applicable national and local regulations and practices.

Copper tubing wall thickness

It may be manufactured from any of five 5 copper alloys C, C, C, C, C that all conform to the chemical composition requirements of alloys containing a minimum of The standard length for copper pipe is 12 feet. Copper pipe is suitable for plumbing, boiler feed lines, refrigeration and for similar purposes. Joints in seamless copper pipe can be threaded, flanged or brazed to fittings of the appropriate joint configuration. The standard length for red brass pipe is 12 feet. Brass pipe is moderately resistant to many corrosive solutions and is often utilized for water supply and distribution.

Used tires grand prairie tx

Inflatable Packer Carriers. The potential difference is often largest at the point where continuity is interrupted. Tools Tools. Types K and L are generally available in both hard drawn straight sections and in rolls of soft anealed tubing, whereas type M and DWV are usually only available in hard drawn straight sections. Some studies have shown significant leaching of the lead into the potable water stream, particularly after long periods of low usage, followed by peak demand periods. The disadvantages are that the fittings used are harder to find and cost significantly more than sweat-type fittings. Strut Nuts. This article uses bare URLs , which are uninformative and vulnerable to link rot. The filler metal flows into the gap between close-fitting parts by capillary action. Flare connections are a labor-intensive method of making connections but are quite reliable over the course of many years.

We may earn revenue from the products available on this page and participate in affiliate programs. Most people know that pipes come in different diameters, but what you may not realize is that some types of copper pipes are thicker than others, too.

Company Name. Anything beyond a few millivolts is significant, and potentials of mV are common. ISBN Clevis Hangers. Pin-holing due to poor grounding or poor bonding occurs typically in homes where the original plumbing has been modified; homeowners may find that a new plastic water filtration device or plastic repair union has interrupted the water pipe's electrical continuity to ground, when they start seeing pinhole water leaks after a recent install. The difference between a ground and a bond is that bonding joins conductors to ensure they are at the same voltage, grounding joins conductors to electrodes that are at the local earth potential. Please improve the article by addressing link rot or discuss this issue on the talk page. Compression fittings use a soft metal or thermoplastic ring the compression ring, "olive" or "ferrule" , which is squeezed onto the pipe and into the fitting by a compression nut. In both the U. Handbook of Corrosion Engineering 1st ed. Structural Attachments. It then flows over the base metal in a process known as wetting and is then cooled to join the work pieces together. In the plumbing trade, the size of copper tubing is measured by its outside diameter in millimeters.

Do not take in a head!