Dt466 engine specs

It looks like you are visiting our site on a browser that is really old. Unfortunately, this means you can't get the full experience. It'd be awesome if you could upgrade to a modern browser, especially Chrome and Firefox as that is the best out there right now. Young and Sons has been a premium diesel engine dt466 engine specs in the Indianapolis for over 65 years, dt466 engine specs.

When it comes to the DT diesel, though, it fits. The DT legend crosses into the industrial, agricultural, and truck realms, but it was the medium-duty truck world where it made the biggest impact. Development of the International Harvester and series engines started in The prime mover for the project was the VP of the Construction Equipment Division of International Harvester, Bill Wallace, who saw a need for a new line of in-house designed and built engines. Reportedly, Wallace had an uphill struggle to get money allocated for the program but lobbied hard and eventually succeeded by expanding the idea to cover the other IH divisions, many of which needed a diesel upgrade.

Dt466 engine specs

The goal for the series engines, in particular, was to replace the aged yet highly venerable DT, which International planned to phase out of production. In virtually every application it was placed in service in, the ci I-6 predecessor had proven near-bulletproof, typically guaranteeing its owner 10, loyal operating hours before requiring an overhaul. Needless to say, the ci, ci, and ci power plants had a lot to live up to. While the DT underwent various changes and updates over the years, foundationally much remained the same. The latter wet-sleeve technology brought heavy-duty durability to the medium-duty diesel segment. As a bonus, the wet sleeve essentially makes each cylinder a stand-alone unit, which means repairs and rebuilds can be executed affordably and in-frame. The original DT featured a 4. Just as the DT and IE engines had shared a common block and the same 5. However, the stroke was the difference in the latter engines, with all of them sharing a common, 4. However, mechanical direct injection—via either rotary injection pump or inline injection pump, and pop-off style injectors—was used exclusively from through , and mechanical injection survived until in some applications. But to meet the stricter EPA emissions standards that had gone into effect in , International switched the bulk of its on-road DT engines over to the Caterpillar-designed HEUI injection system in the HEUI acronym representing hydraulically actuated, electronic controlled unit injector. At this point, the international dt engine was renamed the DTE E for electronic.

There are very slight variations on the injectors between the hp levels, but they all can make substantial power before needing to be replaced. The emissions crunch that began around the turn of the century had a dt466 engine specs effect on the DT engine. I am looking at building a hot shot type rig and using at least a double overdrive for fuel mileage and still be able to run the speed limit up hill loaded, dt466 engine specs.

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. Sort by Oldest first Oldest first Newest first Most reactions. They are oringally from farm tractor useage adpted to truck useage and they were very scussedfull with it.

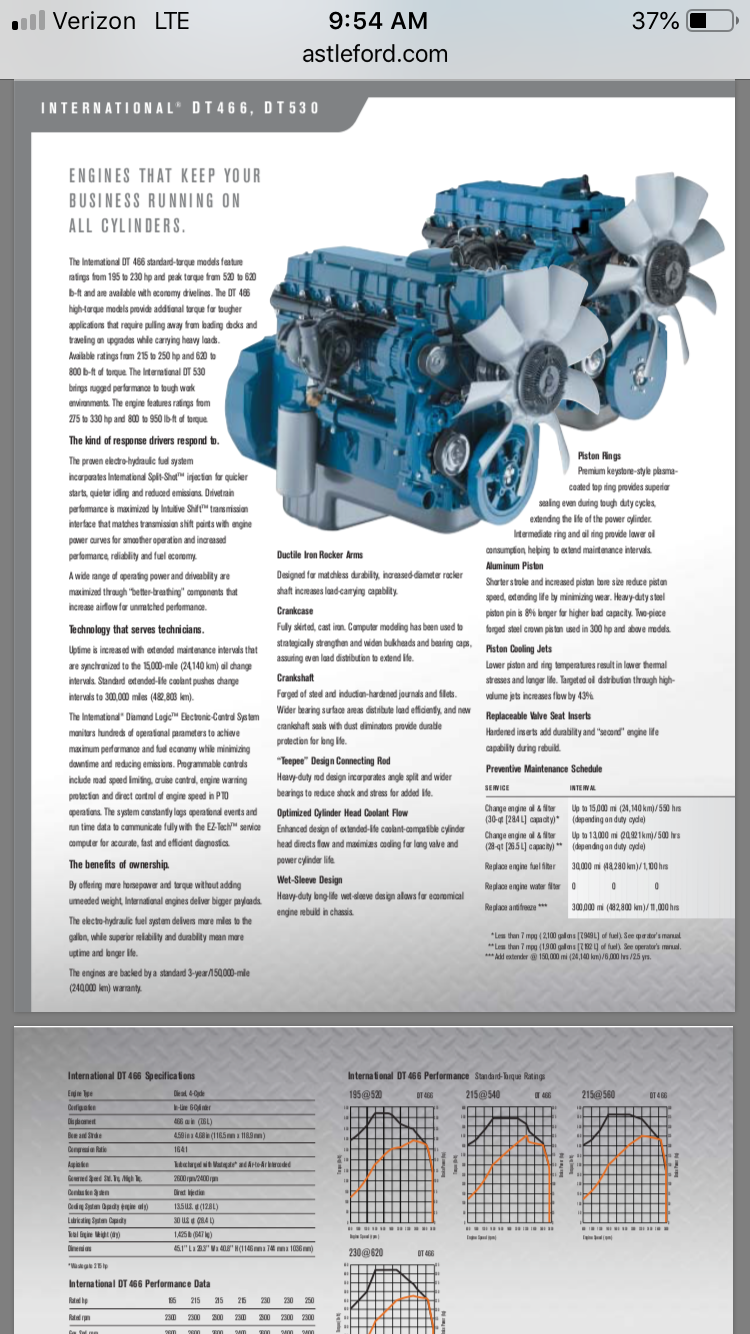

The International DT engine is a 7. It also is utilized in the International CXT, a pickup truck built on the International ton hauler platform. Over one million DT engines have been produced. The DT is a turbocharged diesel. It is, according to Brattain, " the only high volume mid-range diesel engine with replaceable wet sleeve architecture. The DT utilizes six bolts per cylinder for head clamping. The purpose of the six-bolt design is to evenly distribute clamping force and improve the life span of the head gasket. Additionally, the DT design includes valve rotators and an oil cooler thermostat. There are six versions of the International DT engine as of The horsepower engine produces peak horsepower at 2, rpm and pound-feet of torque at 1, rpm.

Dt466 engine specs

All to current models used an HEUI hydraulically actuated electronically controlled unit injector fuel system. The P pump DT was actually used in select applications through the model year, but these are uncommon. Likewise, the HEUI injection system was first introduced for , although these engines coexisted with mechanically injected engines for several years. For , a twin sequential turbocharger system was employed for further improvements in throttle response, overall performance, and reduced emissions. All engines and prior featured a standard fixed geometry turbocharger.

Free knitting patterns for womens vests

The and lines are inexorably locked together, since they shared the same basic architecture, many parts and were built on the same tooling. OHV 4 valves per cylinder [9]. Among the new features were closed-crankcase ventilation and new wiring harnesses. After that, the crankshaft is thoroughly inspected by our quality control department. Testing is also performed according to manufacturer specs and original production standards. I read your site on turning up pumps and didn't see anything other than adjustments, just curious. However, the stroke was the difference in the latter engines, with all of them sharing a common, 4. Posted April 13, Plateau honing was relatively new for but added a lot to the durability and longevity, plus ensured a rapid break-in. Note : We can provide a new oil pump, oil cooler, water pump, turbo, injectors, and fuel pump for an additional cost, but these components will not come assembled to the engine. Link to comment Share on other sites More sharing options The Navistar DT diesel engines are of a wet-sleeve design. For , a twin sequential turbocharger system was employed for further improvements in throttle response, overall performance, and reduced emissions. The DT debuted in the , while the DT appeared in the and the four-wheel drive.

When it comes to the DT diesel, though, it fits.

The DT was added to the Loadstar options list in the summer of as a premium upgrade over the naturally aspirated D, D and D 9. The old rotatory injector pumps can be turned up a lot although the settings are a bit complex. The cylinder sleeve is in contact with the engine coolant, hence the "wet"-sleeve. Plateau honing was relatively new for but added a lot to the durability and longevity, plus ensured a rapid break-in. Among the new features were closed-crankcase ventilation and new wiring harnesses. Read Edit View history. Sled pullers have been using the mechanical 's for years, and performance parts are really reasonable in price. Unfortunately, this means you can't get the full experience. Posted December 10, Additionally, it has been suggested that a wet sleeve cylinder provides greater durability in comparison to a dry sleeve system. Comprehensive Cleaning In an effort to avoid the early termination of both parts and the engine itself, we remove all impurities by stripping the block, head, rods, and camshaft, which are subjected to extensive, meticulous cleaning in a chemical jet wash or hot tank. Sign up. Wider main and rod bearings were also added.

It seems to me it is very good idea. Completely with you I will agree.

Yes, really. I agree with told all above.