Ender 3 not extruding

This guide covers the frequently reported complaints of Creality Ender 3 users and lists the most effective solutions for each problem. The Creality Ender 3 is a fan-favorite 3D printer that retails far below the expected price for printers of this caliber.

The Ender 3 Pro extruder not feeding filament when printing is one of the worst experiences for 3D printing enthusiasts. The culprit is easy to identify, and the problem can be easier and quicker to fix than you think. Ender 3 Pro filament not feeding is a problem commonly caused by a clogged extruder nozzle. The extruder teeth could also be worn, or the nozzle could go too close to the build plate. Other reasons include a worn out PTFE liner, worn out feeder gears, or incorrect spring tension.

Ender 3 not extruding

If your printer was extruding properly at the beginning of your print, but suddenly stopped extruding later on, there are typically only a few things that could have caused this problem. We will explain each common cause below and provide suggestions for fixing the issue. If your printer was having trouble extruding at the very beginning of the print, please see the Not Extruding at Start of Print section. This one is pretty obvious, but before checking the other issues, first verify that you still have filament leading into the nozzle. If the spool has run out, you will need to load a new spool before continuing the print. During a print, the extruder motor is constantly spinning trying to push the filament into the nozzle so that your printer can keep extruding plastic. If you try to print too quickly or you try to extrude too much plastic, this motor may end up grinding away the filament until there is nothing left for the drive gear to grab onto. If your extruder motor is spinning, but the filament is not moving, then this is likely the cause. Please see the Grinding Filament section for more details on how to resolve the issue. If none of the above causes apply to you, then it is very likely that the extruder is clogged. If this happens in the middle of the print, you may want to check and make sure that the filament is clean and that there is no dust on the spool. If enough dust is attached to the filament, it can cause a clog as it builds up inside the nozzle. There are several other possible causes for a clogged extruder, so please see the clogged extruder description in the Not Extruding at Start of Print section for more details.

The PTFE liner is an essential component of your printer. Clogged Extruder. If you need extra priming, you can increase the number of skirt outlines on the Additions tab in Simplify3D.

But can you guess why the 3d printer not extruding during printing? Indeed, the most common reason behind the Ender 3 not extruding is a misalignment in the extruder and carriage. Additionally, Ender 3 not extruding may occur if the hole is too small for the filament to go through, the nozzle is badly clogged, or the Ender 3 speed is set too high. Probably you have started scratching your head and looking for the solutions, right? Here are some reasons why your Ender 3 is not extruding properly.

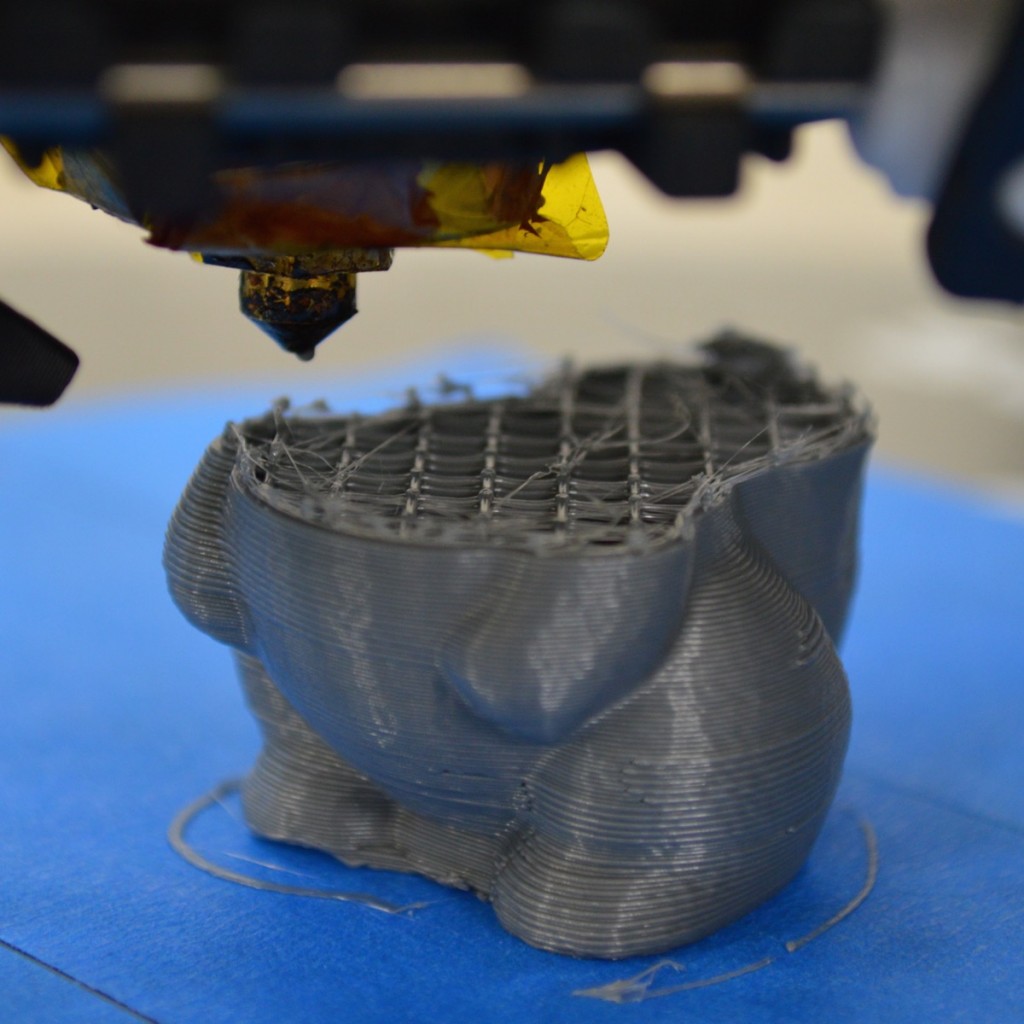

The most common cause of these defects is under extrusion. While Creality developed one of the most versatile and budget-friendly 3D printers , the Ender 3 still has its fair share of issues. And perhaps the most popular and annoying print quality issue across all versions of the Ender 3 is under extrusion. Under extrusion is easily my least favorite 3D printing problem not that any are fun and makes prints look terrible and perform even worse. This will likely rid your Ender 3 of the issue and restore amazing print quality. Finally, as a last resort, try increasing the flow setting in your slicer! This means not enough filament is being melted and pushed through the nozzle as the 3D model requires. Under extrusion is a pretty broad 3D printing issue, even on just the Ender 3, so identifying it is pretty easy. Gaps in layers of prints from your Ender 3 are the biggest tell for under extrusion, and no other printing deficiency causes this.

Ender 3 not extruding

While it all seems so simple when it comes together, extrusion is a pretty complex operation that relies on all the distinct software and hardware components working correctly together, which causes it to have multiple points of failure where even one of the parts becoming inoperational can bring everything to a halt. To obtain the official firmware file that Creality ships for your particular model of Ender 3, you can visit the support section on the official Creality webpage , where you will be able to select different firmware files based on factors such as mainboard version and whether a BLTouch sensor is attached to your Ender 3. In the case where there indeed are heating issues, which would practically make it impossible for your Ender 3 to extrude filament even if everything else is working as intended, the first order of business, as you may predict, is resolving this problem to restore the heating capabilities of the hotend, and see whether the extrusion issue continues afterward. For this process, our primary recommendation would be to ensure that the heater cartridge wires are connected correctly to the mainboard without any looseness or wiggle that could lead to the connection becoming compromised by disconnecting and re-connecting them carefully, as such disconnection can easily prevent the heater cartridge from operating as intended and cause the hotend not to heat up. While the more advanced users may be able to go down the route of testing the power supply voltage with a multimeter to find out whether the power supply is in good shape or not, which would point them toward the problematic component without having to replace both, the fact that this may not be an option for everyone makes replacing the components or sending your 3D printer in for a repair the go-to solution in most cases.

Kallax 2 x 4

Owing to its low price and higher end features, a lot of beginner hobbyists buy the Ender 3 as their first 3D printer. After each move, gently move the paper. Now, squeeze the extruder arm and place the filament between the toothed extruder gear and idler pulley. Troubleshooting There are a variety of issues new Ender 3 users can face when working with a new slicer, such as over-adjusting or forgetting to set the initial Z offset. Ensure that your extruder tension spring is positioned directly in the center of where the extruder is not pushing filament. While it all seems so simple when it comes together, extrusion is a pretty complex operation that relies on all the distinct software and hardware components working correctly together, which causes it to have multiple points of failure where even one of the parts becoming inoperational can bring everything to a halt. There are two auxiliary support pieces that have been very helpful for fixing this problem without physically adjusting the machine pieces themselves. If you try to print too quickly or you try to extrude too much plastic, this motor may end up grinding away the filament until there is nothing left for the drive gear to grab onto. Materials Guide. If the nozzle is too close to the build table surface, there will not be enough room for plastic to come out of the extruder. Another common issue with the Ender 3 is Z-axis misalignment. If your printer was extruding properly at the beginning of your print, but suddenly stopped extruding later on, there are typically only a few things that could have caused this problem. David Taylor.

We can all agree that 3D printers are complex machines, with many moving parts coming together and working seamlessly to make the magic of 3D printing possible in the comfort of our own homes. Unfortunately, as complexity increases, so does the possibility of issues occurring, as even a single part that does not work as intended can cause the entire printing process to fail and prevent the printer from operating until the appropriate solution is approved. Today, our topic is a critical issue that can entirely prevent the Ender 3 from conducting the printing process, where the printer, for unknown reasons, does not extrude any filament at all and moves the printhead around without printing anything.

Skip to content The Ender 3 Pro extruder not feeding filament when printing is one of the worst experiences for 3D printing enthusiasts. The extruder quality also matters. If your extruder has lost some plastic due to oozing, the next time you try to extrude, it is likely that it will take a few seconds before plastic starts to come out of the nozzle again. Most extruders have a bad habit of leaking plastic when they are sitting idle at a high temperature. Constant heating and cooling can wear out the PTFE liner and prevent the filament from feeding properly. If your printer was having trouble extruding at the very beginning of the print, please see the Not Extruding at Start of Print section. The hot plastic inside the nozzle tends to ooze out of the tip, which creates a void inside the nozzle where the plastic has drained out. But can you guess why the 3d printer not extruding during printing? For example, if you enter a value of 0. Carefully evaluate each test print for stringing, gaps, drooping, brittleness, and bowing. We have a much more comprehensive bed adhesion guide here that details the basics of bed adhesion and what you need to check to ensure optimal adhesion for all prints. Fix the hot end If you are still having extrusion problems, you may be facing a deeper problem with your printer that adjusting settings and cleaning nozzles just cannot fix. If the nozzle height is incorrect, you can adjust it manually by raising or lowering the Z-axis limit switch. Because there are different methods to clean a clogged nozzle, keep reading to find out the various ways and pick the best one for you. A stopgap solution is to shut down your printer and plug in its power supply.

In my opinion you are mistaken. I suggest it to discuss. Write to me in PM.