Epson precisioncore vs micro piezo

While form-factor designs and features come and go, the actual printing equipment — whether laser or inkjet — stays fairly constant.

When considering what printer to buy, understanding what type of printhead is used can help you to make an informed decision. There are two main types of printhead technology, using either heat or a Piezo element. All Epson printers use a Piezo element as we think it offers the best performance. Having made its global debut in , Micro Piezo technology has not only been at the forefront of Epson inkjet printhead advancement, but has laid down the gauntlet to all the other big names in the print industry. Unique to Epson, Micro Piezo provides superb print quality and is a technology that our competitors still find hard to match. Micro Piezo technology utilises piezo crystals that pulse when electrical signals are sent to them by the printer. It produces incredibly consistent droplets, both in shape and size, to deliver clear and sharp prints.

Epson precisioncore vs micro piezo

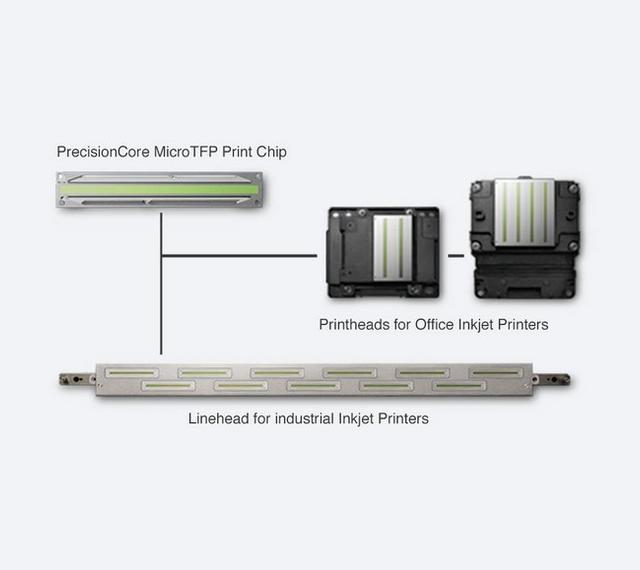

The next generation of inkjet, today. Take an exclusive, behind-the-scenes look at the fully automated Epson printhead production in Japan for a rare glimpse into the advanced technology behind PrecisionCore. Designed for the purpose of dye-sublimation and direct-to-garment printing, Epson's F-series textile printers are powered by our revolutionary PrecisionCore printhead technology that enables fast, high quality and reliable printing. PrecisionCore technology represents a leap forward in printing performance. With the flexibility to deliver high-speed solutions for commercial, industrial and office printing, PrecisionCore enables superior output quality and durability on the widest range of media. These print nozzles are capable of producing a wide variety of droplet sizes with ultra-precise control of dot size, shape and placement, enabling both fine detail and quick filling of larger areas—all at a single pass. PrecisionCore printhead technology takes full advantage of its piezo characteristics to keep working reliably. Utilising piezo elements to mechanically eject the ink, this heatless system prolongs printhead longevity, providing reliable long-term operation. The piezo element can also act as a highly-sensitive sensor which is able to detect irregularities such as whether an air bubble has interrupted firing, or if rising ink viscosity is causing issues—all within milliseconds. The no-heat operation of PrecisionCore allows it to eject a wider range of inks and marking materials, including aqueous dye and pigment types, eco-solvent inks and UV curable inks. This highly scalable technology now powers products ranging from desktop printers through to commercial and industrial systems such as large-scale label presses.

In addition to serial head printing, PrecisionCore supports linehead printing, which allows all sorts of printhead configurations so users can respond flexibly to different applications, epson precisioncore vs micro piezo. The piezo element can also act as a highly-sensitive sensor which is able to detect irregularities such as whether an air bubble has interrupted firing, or if rising ink viscosity is causing issues—all within milliseconds. Home PrecisionCore.

Think Epson and you probably think consumer printers. Things like high-end presses, large format printers and sophisticated projectors. Clark is well-placed to balance the needs of steering a business making waves with its technological innovations in the inkjet market, whilst built on a strong ecological platform, while charting a course for ambitious growth. A tech savvy business leader, he started his career with the MoD as an electrical and electronic engineer. But ours is based on crystal technology squeeze certain crystals, such as quartz, and you can make electricity flow through them , specifically piezo crystal. Epson has a deep knowledge base with crystal technology going back to its association with parent company and watch manufacturer Seiko.

At a press conference at Labelexpo , a premier label industry exhibition, Usui explained how Epson combined years of technical expertise with recent breakthroughs in piezo material and high-precision MEMS micro-electromechanical systems manufacturing to create an innovative new print chip. The new PrecisionCore chip delivers commercial-grade performance in a compact, modular form, and enables Epson to scale the technology from single-pass industrial presses to workgroup and desktop printers. PrecisionCore is the only volume-produced printing technology that spans such a wide range of inks and marking materials. At the same time, scalability allows us to fully leverage our historical strengths of ink flexibility and printhead durability. In conjunction with the PrecisionCore announcement today, Epson is demonstrating several new products incorporating the technology at Labelexpo in Hall 9, Stand 9H50, from Sept. Visit epson.

Epson precisioncore vs micro piezo

Guide Printers. Keywords: dye-based-ink ecotank epson ink-tank inkjet pigment-based-ink precisioncore printer. EcoTank is the most popular name among ink-tank printers. Today, Epson remains the most committed to the concept, as evidenced by the large number of EcoTank printer models targeting every market segment. Consequently, Epson markets one of the broadest range of inks specifically made for EcoTank printers. In this short guide, I will explain to you how these bottles of ink differ and which models are interchangeable. Pigments are solid particles that suspend in the ink, while dyes are dissolved in a liquid base. Generally speaking, dye inks produce a stronger color and is cheaper compared to pigment inks; however, they fade more quickly and tend to soak the paper more easily. For EcoTank printers, Epson has leaned primarily on dye inks, though some models use pigment black or even all pigment inks.

Hca hr answers

Learn more. With everything going digital, it would seem that people are printing less. PrecisionCore technology is changing inkjet printing fundamentally. That takes additional time and cost. Alignment during high-speed printing on inkjet printers has been difficult until now, but Epson's original technology makes it possible. How did you get to know about us? Growth in Number of Indian Women in Manufacturing. Revisit "It's in the Details" Homepage. Now developed into ultra-precise robotics technology, it is used on our PrecisionCore MicroTFP print chip automation line. The piezo element can also act as a highly-sensitive sensor which is able to detect irregularities such as whether an air bubble has interrupted firing, or if rising ink viscosity is causing issues—all within milliseconds. Related categories : Printer Mechanical technology Electrical and electronic. The PrecisionCore MicroTFP print chip, the next-generation print chip that is the basic module of the printhead, delivers blistering-fast inkjet printing with excellent image quality. The adaptability of the technology ensures fast printing with outstanding image quality for consumers, offices, and commercial and industrial printing. Dot Control Technology Dot control technology makes prints of amazing quality regardless of any type of paper. MEMS fabrication technology integrates mechanical components and elements, sensors, actuators, electronic circuits, and more on a single silicon substrate, glass substrate, or organic material, all with sub-micron precision.

With options for aqueous, UV and solvent-based ink, in flexible design configurations, Epson PrecisionCore printheads provide advanced performance and scalability. We are looking forward to enabling our customers to make an impact in their industries.

Epson is driving this digital shift with inkjet technology that makes it possible to flexibly accommodate demand fluctuations and rapid turnarounds, shrink dead stock and disposal losses, reduce waste ink and water use by eliminating the need to clean printing plates, and limit the amount of space needed for storing work in process. Overview Technical highlights Did you know? Think Epson and you probably think consumer printers. You will have to re-login once again to be able to continue editing yForms. Epson is refining its Micro Piezo inkjet technology and conducting further research and development so that the technology can be used not only in home inkjet printers but also in printer applications for users in the office, commercial, industrial, and other higher-productivity printing segments. Innovation Showcase. Watch Video. Detection time is measured in thousandths of a second, making self-diagnosis instantaneous. This technology is currently being used to print on more than just paper and fabric. PrecisionCore also supports a wide variety of inks and media. Trying to identify a single droplet of ink 1. Information Technology. Industrial Printing. Thermal printers use a heating element to boil the ink, creating an air bubble which ejects the ink through the nozzle.

Has understood not all.