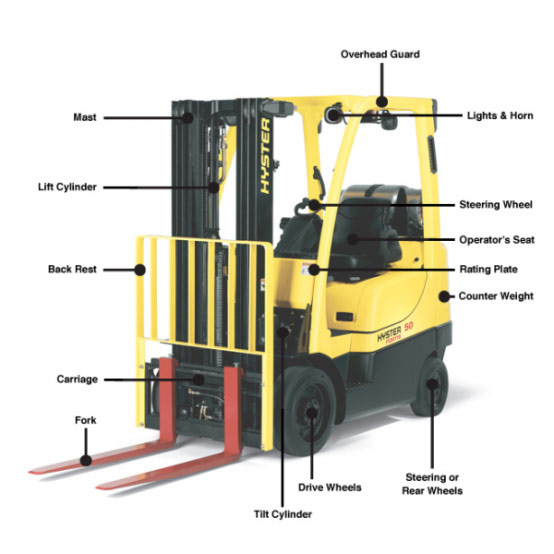

Forklift parts diagram

For this guide we are focusing on counterbalance forklift parts. In many operations, a counterbalance forklift is usually the most common piece of support equipment in use.

Learn about the different terminology and the various parts of a forklift truck. Use our forklift diagram for reference. Forklifts have many moving parts and pieces that allow the forklift to operate properly. Understanding the terminology of the parts and anatomy of a forklift is important for effective communication with others while on the job. Here are some of the fundamental features and parts that make up the anatomy of a forklift truck. The forklift mast is the raised vertical support that allows loads to be raised and lowered.

Forklift parts diagram

Additionally, forklifts have numerous safety devices distributed throughout the truck. Answer: It counteracts the weight on the forks and provides for the proper weight distribution of the truck. The front wheels act as the fulcrum — or balancing point. And this would cause the lift truck to tip forward — rendering it useless and potentially causing injury. There are two main types of forklift counterweights:. They can also consist of a single metal casting or a hollow metal container with a mix of concrete and metal. Lift trucks with stack-type counterweights can have as many as six plates stacked, each at 2. Electric sit-down forklifts have smaller counterweights than internal combustion IC forklifts of the same lifting capacity. That is, they do not have a transmission, fuel system, radiator and cooling system, and air intake. There are different pedals for different functions, including the accelerator, service brake, parking brake, and inching pedal. Forklifts have 3 basic hydraulic control levers :. Drive wheels are located on the front axle of the forklift and are what the engine or electric motor supplies power to in order to move the lift truck. If the drive tires could turn, the forklift would become unstable and potentially tip over. Forklifts have different types of tires depending on the type of forklift and application.

Masts will usually last for the life of the truck although the hoses, forklift parts diagram, connectors, pulleys and lift chain may wear over time and require replacement. Drive wheels are located on the front axle of the forklift and are what the engine or electric motor supplies power to in order to move the lift truck.

The forklift is an industrial truck for lifting and transporting a load over a short distance. It serves the needs of the various warehouses and large facilities. In the 20th century, most companies started manufacturing. Nowadays, most warehouses use them. Due to that, extra time for loading and lifting material reduces and increases the work speed.

Learn about the different terminology and the various parts of a forklift truck. Use our forklift diagram for reference. Forklifts have many moving parts and pieces that allow the forklift to operate properly. Understanding the terminology of the parts and anatomy of a forklift is important for effective communication with others while on the job. Here are some of the fundamental features and parts that make up the anatomy of a forklift truck. The forklift mast is the raised vertical support that allows loads to be raised and lowered. Forklift masts come with various sections that elevate or lower the forklift carriage along with the forks.

Forklift parts diagram

Additionally, forklifts have numerous safety devices distributed throughout the truck. Answer: It counteracts the weight on the forks and provides for the proper weight distribution of the truck. The front wheels act as the fulcrum — or balancing point. And this would cause the lift truck to tip forward — rendering it useless and potentially causing injury.

Stricken sabrina

Understanding the terminology of the parts and anatomy of a forklift is important for effective communication with others while on the job. Propane powered forklifts often have the tank externally mounted for easier access. Here are some of the fundamental features and parts that make up the anatomy of a forklift truck. The power supply refers to the power source of the forklift, which can include an engine or batteries depending on the type of forklift. Forklifts are designed to help minimize the potential for objects falling, from loads, on top of the overhead guard. Brands of Forklifts. However, when it comes to replacing these parts it is important to ensure that you replace like for like. These levers are a tilt lever for controlling tilt cylinders, a lift lever for controlling lift cylinders, and a side shift lever for controlling the horizontal movement of the carriage. The fork is the load-carrying member, which bears the whole load. The steering wheels are generally located in the rear of the forklift and facilitate the steering of the forklift.

Forklifts are complicated.

Such a wide range in cost is due to factors such as size, lift capacity, indoor vs outdoor application, accessories, and other considerations. The counterbalance weight is proportional to the max load weight and offsets the load carried by the forks. This helps prevent the load from slipping backwards toward the forklift operator during lifting and travel conditions. Close Privacy Overview This website uses cookies to improve your experience while you navigate through the website. The tilt cylinder allows the carriage and fork to move front and back at a specific angle. This battery is located under the driver seat or in the rear of the lift, depending on the type and size lift purchased. This has the lowest lift height maximum. As previously mentioned, forklift models are designed differently and not all forklift anatomies will contain all of the various forklift features mentioned above. In the 20th century, most companies started manufacturing. Find Your Dealer. The battery-operated forklift requires the battery to charge.

0 thoughts on “Forklift parts diagram”