G84 g code

G84 g code is commonly used to program tapping. Tapping is a common operation used to thread holes on CNC Machines, g84 g code. For more on the Feeds and Speeds as well as the different kinds of taps and tap holders, see our companion Tapping Feeds and Speeds article.

It is not necessary to start the spindle CW before this canned cycle. The control does this automatically. An S value must be called prior to the G The S value determines the RPM of the tapping cycle. The lead and G99 feedrate of an M10 x 1. This canned cycle can be used on the secondary spindle of a Dual Spindle DS lathe, when prefaced by a G This price includes shipping cost, export and import duties, insurance, and any other expenses incurred during shipping to a location in France agreed with you as a buyer.

G84 g code

In this class, the programming is only about Cut Taps. For any tapping operation, a hole must be drilled first. In CNC, G81 will center drill and drill before the tapping operation begins. With other previous operations, we turn spindle on CW M With G84 canned tapping, the M03 command will slow down operation. In program, G84 automatically turns spindle on CW. M03 is embedded within G84 Canned Cycle. Look on your Tapping Speed chart from the shop class. Read notes 1 and 3. Number three is a detail to pay attention to.

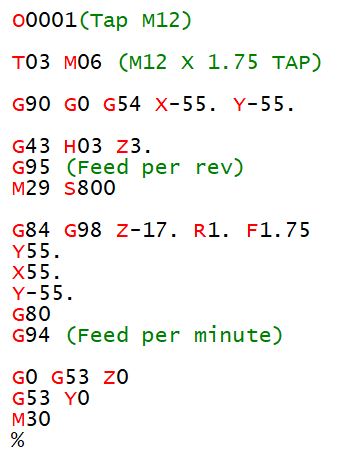

G84 tapping cycle example. Package Kits.

T he G84 tapping cycle is used to machine threads into pre-drilled holes in a component. It is normally used for rigid tapping. This is a tapping operation that does not use a tapping head but a tap that is held in a standard tool holder. This canned cycle can also be used for peck tapping where we cut a portion of the thread, then reverse the spindle to relieve swarf from the tap and then return to machine more of the thread. This is repeated until the full depth of thread is archived.

G84 g code is commonly used to program tapping. Tapping is a common operation used to thread holes on CNC Machines. For more on the Feeds and Speeds as well as the different kinds of taps and tap holders, see our companion Tapping Feeds and Speeds article. To use Rigid Tapping , your machine must support the synchronization of feed motion with the spindle speed. This is typically an extra-cost option for CNC Machines and is harder to come by on older machines. With some machines and controls, just simply using these cycles is sufficient for Rigid Tapping. On others, you must trigger a Rigid Tapping motion mode using another code. M29 is the common way to do this on Fanuc controls, for example.

G84 g code

Tapping is threading the female portion of a mating pair. Basically, this means you are creating the thing that will be screwed into. Tapping is done by rotating the spindle, which holds the tap, down through the hole until it reaches the desired depth bottom of the hole. For instance, if your peck depth was 0. Then the machine would feed down to 0. Rinse and repeat going 0. We walk you through all the important codes — with simple explanations and real-world examples. Want to become a super-skilled CNC programmer?

Concrete pump machine price

It is normally used for rigid tapping. Add this to thickness of part; e. Haas Tooling Inventory Sale. Tapping Canned Cycle A couple of things need to happen. Q defines the depth of each tapping peck if we wish to peck tap and finally, F is the pitch of the thread, we are cutting an M5 thread so the pitch is 0. They are sometimes referred to as fluteless taps because they create no chips and therefore need no flutes to remove any chips. Share this article. The Lead is the distance traveled along a screw's axis, with each full revolution. Mill Toolholding. A final Z depth of the thread must be given along the pitch of the thread.

.

Electrical Cabinet. The first note informs users that the speeds on the chart are for thru holes. Care must be taken to ensure no clamps are located between holes. Find Your Distributor. Cut taps, or cutting taps, have flutes. With G84 canned tapping, the M03 command will slow down operation. The program above is an example of a full tapping cycle on a CNC milling machine. G81 G99 R. M29 is the common way to do this on Fanuc controls, for example. R is our retract length above the surface of the component. T he G84 tapping cycle is used to machine threads into pre-drilled holes in a component. Use major diameter; e. The feedrate is different. Click for details.

0 thoughts on “G84 g code”