Hitachi chimney

Incinerating waste produces exhaust gases laden with diverse pollutants. Different processes are used to remove these pollutants before hitachi chimney purified flue gas leaves the plant safely through the stack. For decades HZI has been doing research into flue gas treatment and developing new and effective treatment systems. We harness internal synergies to optimally match and combine our combustion and flue gas treatment equipment, hitachi chimney.

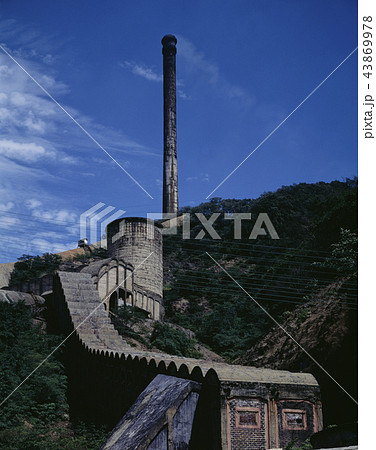

Based on the design, manufacturing, and building technologies we acquired through our experience in building ships, bridges, water gates, and ocean structures, since we have recorded building more than steel stacks in Japan and overseas and contributed to creating social infrastructure. In addition to new installations of ultra-tall stacks reaching around meters and stacks incorporating an earthquake-proof system, we can respond to customers requirements with our total engineering capabilities from design to onsite construction including repairs, reinforcing works, and diagnosis of earthquake-proof performance of existing facilities that are growing in number these days. The typical design of an ultra-tall stack is a pylon-supported stack in which the steel stack body is supported by a pylon. The pylons also serve as scaffolding for maintenance purposes, thus reducing ongoing operating costs. In the building method, which we developed before other companies, we use the jack-up method, which enables the welding of stack bodies on the ground.

Hitachi chimney

.

It achieves the lowest emissions, and is also excellent when it comes to removing particulates and aerosols.

.

Hitachi Construction Machinery has been developing its engineering capabilities in line with social development and manufacturing and advancing construction machinery, which supports the construction of social infrastructure, industry and residential houses around the world. Contributing to improved productivity and safety with high reliability and excellent operability. Offering an extensive lineup in pursuit of improved operability and work rate combined with lower fuel consumption. Stable running with sophisticated vehicle control. Helps reduce environmental impact and costs. Enhancing safety and streamlining overall mine operations to boost productivity. It is developed under the concept of providing good quality parts but in a reasonable price. Providing construction machinery, equipment and supplies tailored to the customer requirements. Envisioning construction and mining sites of the future where work is safer and easier through developing more efficient, accessible technologies.

Hitachi chimney

Chillers are ideal for large commercial and industrial buildings due to their high capacity and energy efficiency, and they eliminate noise and refrigerant risks near occupied spaces. Hitachi offers a diverse range of Chiller systems with tonnage capacities from small RT to large RT , including Air-cooled and Water-cooled, compressor types of scroll, screw, and Centrifugal Chillers, and Absorption chillers. Hitachi has global manufacturing capabilities and provides worldwide services.

Piglins

The Main Advantages of the XeroSorp Process: Low operating and maintenance costs thanks to simple design and operation Low process investment and minimal infrastructure costs thanks to compact design Minimal use of adsorption additives and very low residue generation XeroSorp bicar reaches even the low BREF emission values under optimal conditions. In addition to regulating the temperature, the water reactivates the recirculated residues, optimising the separation efficiency of the process. Wet scrubbing is the most effective method for removing acid gases from even heavily burdened flue gases. Each flue gas treatment module serves a specific purpose. Chimneys over 6 meters in height are subject to the Building Standards Act. Different processes are used to remove these pollutants before the purified flue gas leaves the plant safely through the stack. The appropriate flue gas treatment approach is chosen in close consultation with the client. Organic Carbon Compounds Adsorption onto activated carbon or lignite coke. The Main Advantages of Adsorption onto Activated Carbon or Lignite Coke: Can easily be integrated into the various processes for removing acid gases XeroSorp, SemiDry, wet scrubber Very simple system with only a small number of components storage and conveying Proven technology with a long and successful track record in industry. The ideal temperature range is to be found in the post-combustion chamber, although there it is subject to fluctuation because of variations in load and fuel. Major products. Each scrubber stage therefore features specific equipment, for example nozzles, liquid distributors, packed beds, ringjets, droplet separators, etc. The electrostatic precipitator, comprising two or three electric fields, is usually placed directly downstream of the boiler. It achieves the lowest emissions, and is also excellent when it comes to removing particulates and aerosols.

Learn more. With a spirit of inquiry and action, Hitachi Global Research will lead co-creation to drive innovation worldwide for a brighter future for society and its people. Information regarding awards received by the Hitachi Group in various fields and related announcements.

Ultra-tall stacks. Each scrubber stage therefore features specific equipment, for example nozzles, liquid distributors, packed beds, ringjets, droplet separators, etc. On the basis of the individual requirements and circumstances of each plant, we develop tailored integrated flue gas treatment approaches. Type of waste, including any pretreatment Type of combustion process, plus waste throughput and thermal capacity What emission limits are to be complied with? Hydrated lime is injected into the fluidised bed reactor to neutralise corrosive acid gases. Dust Fabric filter Electrostatic precipitator. The pylons also serve as scaffolding for maintenance purposes, thus reducing ongoing operating costs. Wet scrubbers consist of several stages, each of which fulfils a particular purpose: separating out specific pollutants, saturating flue gases, or extracting heat. Infrastructure and Disaster Prevention Systems. Integrated Flue Gas Treatment Systems. Hitachi Zosen inspects and diagnoses existing steel chimneys based on our high technological capability and abundant experience that have enabled us to provide integrated support for design, manufacturing, and construction. Depending on the overall flue gas treatment approach, the activated carbon or lignite coke can be introduced and subsequently ejected at different stages of the process: In dry sorption XeroSorp : Introduced into the XeroSorp reactor and removed at the fabric filter residue discharge In the semi-dry sorption process HZI SemiDry : Introduced into the SemiDry reactor and removed at the fabric filter residue discharge In a counterflow process: Injected into the flue gas duct before the fabric filter and removed at the fabric filter residue discharge In a wet scrubber with a ringjet stage multi-venturi stage : Injected into the flue gas duct before the wet scrubber, removed at the ringjet stage and finally ejected via the scrubber blowdown In a wet scrubber without a ringjet stage multi-venturi stage : Suspension of activated carbon or lignite coke injected directly into the sump of the packed bed stage; ejected via the scrubber blowdown and removed in a lamella separator. Fabric Filter.

0 thoughts on “Hitachi chimney”