Horizontal boring machine line diagram

Horizontal 2.

A boring machine is a machine which is used for boring large holes on the articles or work items which are not possible to move or rotate on the machine. It is one of the most useful machines which is used on heavy articles like engines, frames, cylinders, land etc. Horizontal boring machines are used to bore large holes in a horizontal direction. Horizontal boring machine is the heavy duty machinery which is used for the boring on large work items which are more in immovable nature, heavy, difficult to balance etc. And it performs multiple tasks like boring, turning, milling, cutting, grinding etc. The main difference between the vertical boring machines and the horizontal boring machine is the machine installation and configuration pattern. That means the positioning of operation tools and the placement of work item.

Horizontal boring machine line diagram

Toll free Mills and lathes are highly versatile machine tools that form the centerpiece of most machine shop floors. Boring mills, on the other hand, are more specialized, meaning they frequently appear as part of a larger production line. The easiest way to describe what a boring mill does is to say that a boring mill drills holes. The reality is slightly more complex. Boring mills are more frequently used to enlarge holes that have already been drilled. While standard mills and lathes can also be used to rough out or finish boring holes, boring mills provide extra power and stability. This ensures a more precise finish to the hole itself and also preserves the dimensions of the piece. Boring mills operate on the same general principles as lathes, with a rotating spindle. Unlike lathes, boring mills are always used on internal geometries rather than the external geometries of a part. For example: a machinist could use a lathe to create a sphere out of a block of material. Then that same sphere could be placed in a boring mill to create a perfectly even hole through the center of the sphere. For smaller workpieces, vertical boring mills function almost exactly like a vertical lathe or turning center.

Unit 2 Unit 2.

Download Now Download to read offline. Recommended Single Point Cutting Tools. Boring machine. Capston and turrent lathe. Capston and turrent lathe Yuga Aravind Kumar. Tool geometry. Tool geometry Prem Kumar Soni.

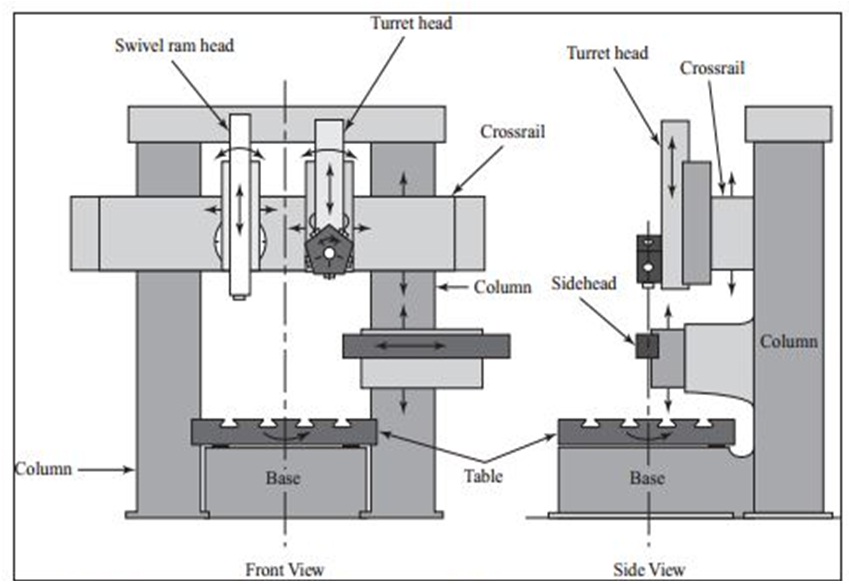

Horizontal Boring Machine:. The horizontal boring mill is also known as horizontal boring, drilling and milling machine, and is intended to perform operations on relatively large pieces which cannot be rotated easily, are irregular and unsymmetrical, and require operations on many surfaces. It also indicates the relative movements of its sliding and rotating elements. It may be noted that the main spindle can be rotated in either direction. It is possible to feed the main spindle axially. The work table can be traversed along and across the machine bed. It is possible to machine a flat surface square with bored hole in one setting of workpiece by mounting facing head over the spindle. The four basic types of machines are described below:. Table-Type Machine:. It is perhaps the most familiar machine and consists of headstock, column, base, table, saddle, end support and bed.

Horizontal boring machine line diagram

The Engineers Post. Its parts, types, tools and operations. In order to better assist you in understanding, we will go over every aspect of the horizontal boring machine in this article. The boring machine is one of the most versatile machine tools used to bore holes in large and heavy parts such as engine frames, steam engine cylinders, machine housing, etc.

Minuteman press anchorage

What is a boring mill? In a horizontal boring machine, the work is supported on a table which is constant and the tool turns into a horizontal axis. Leave a Reply Cancel reply Your email address will not be published. The cutter is lowered into the rotating workpiece, using the motion of the part to bore out the hole. Strictly Necessary Cookies Strictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings. One of the major uses is when parts are larger in size and crane is to be placed overhead. Theory of Metal Cutting. You can also download The PDF file of this article at the end. Types of Horizontal Boring Machines 3. There are various methods of attaching cutters to boring bars. Boring heads have the maximum permissible diameter.

A horizontal boring machine or horizontal boring mill is a machine tool which bores holes in a horizontal direction. There are three main types — table, planer and floor. A horizontal boring machine has its work spindle parallel to the ground and work table.

Holes are bored by using boring bars. Double Column VBM. What is a Horizontal Boring Machine? The machine essentially consists of a bed, headstock supporting column, end supporting column, headstock, saddle and table, and boring bar. Heat treated bars of medium carbon steel alloyed with chromium and manganese are using where the severe cutting condition exists. Vertical Boring Machine In the vertical type of boring machine configuration, the operational tool is placed like normal lathe machinery and performs all the normal lathe machinery functions like cutting, turning, boring, threading etc. This site uses Akismet to reduce spam. Privacy Overview. The cutting tool mounts to the end of a rotating spindle, which is advanced into the workpiece. Shapper Planner Shapper Planner. The maximum diameter of the bar employed is ordinarily not larger than the spindle diameter, and the length is such that it can reach the end column support.

Willingly I accept. The question is interesting, I too will take part in discussion. Together we can come to a right answer. I am assured.

I think, that you commit an error. Let's discuss. Write to me in PM.