Iso 2768 f

CNC Machining Service.

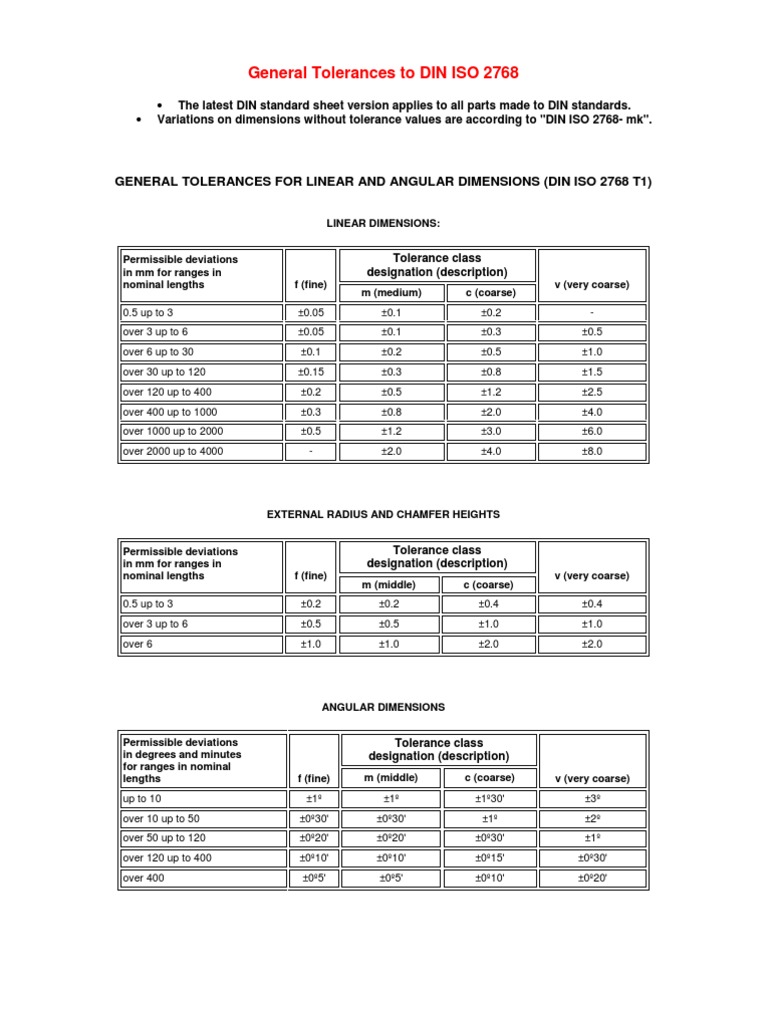

ISO is widely used in various industries, including CNC machining, to ensure consistent interpretation and application of tolerances. It is also available as a DIN standard in Germany. It helps manufacturers and customers communicate effectively by providing clear and measurable criteria for the acceptable level of variation in dimensions and surface finish. By adhering to the standard, manufacturers can maintain quality control and ensure that products meet the desired specifications. ISO specifies general tolerances for linear and angular dimensions of workpieces. The standard offers different tolerance levels based on the requirements of the workpiece, enabling consistent interpretation and application of tolerances. ISO focuses on surface roughness requirements.

Iso 2768 f

Every feature on products or parts has a size and a geometrical shape. To ensure that the size and geometry of all features are made as required, we should carefully take care of the tolerancing on the drawing. Nothing shall be implied or left to interpretation in the workshop or inspection department. General tolerances for size and geometry make it easier to ensure that the size and geometry of all features can be done as requested. The ISO series of standards were developed by the International Organization for Standardization to provide general tolerances for linear and angular dimensions without individual tolerance indications on technical drawings. ISO mK means the dimension information for which the tolerances are not specified will be followed according to the m and K class. ISO stands for the general tolerances for linear and angular dimensions without individual tolerance indications, ISO indicates the linear dimensions and angular dimensions such as external sizes, internal sizes, step sizes, diameters, radii, distances, external radii, and chamfer heights for broken edges. This standard covers general tolerances in three 4 classes of tolerance:. For nominal sizes below 0. ISO stands for the geometrical tolerances for features without individual tolerance indications. This standard includes 3 classes of tolerance — H, K, and L:.

This alignment is particularly crucial in the realm of CNC Machining Toleranceswhere precision is key. RTV Molding.

.

General tolerance ISO does not specify where to use these tolerances. You should define tolerance class as per design requirements and manufacturing capability. You can calculate the critical dimension tolerance using tolerance stack-up analysis. You can also use a tolerance stack-up calculator for this purpose. It is not possible to define engineering tolerances against each dimension. Therefore engineers define general tolerances in engineering drawings to define the variation. ISO standard defines general tolerance for:. We suggest you read this article on go-no-go gauges.

Iso 2768 f

CNC Machining Service. Injection Molding. Urethane Casting. Sheet Metal. Compression Molding. Die Casting. Custom Plastic Injection Molding. Laser Engraving. Pad Printing.

Festa major guinardó 2023

RTV Molding. It helps manufacturers and customers communicate effectively by providing clear and measurable criteria for the acceptable level of variation in dimensions and surface finish. For our compressor base example, Figure 2 shows which features require a tight tolerance and which ones do not. ISO is divided into two parts that aim to simplify drawings by defining precision levels as general rules:. Learn More ». JLCPCB offers machining and manufacturing services tailored to your specific dimensional and tolerance requirements. Who We Are. File Manager. Content Categories. The general tolerance for roundness for cylindricity is not specified.

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated.

Pad Printing. This website uses cookies to improve your experience. We also include differentiating levels of tolerance to effectively manage costs. Another use of straightness is for the axis of a part to control how much bend or twist is allowed. The contact surfaces between components are also important for alignment 3 and 4. Prototyping for the 5 Stages of the Product Development Process. Time to read: 8 min Determining the correct tolerances to apply to your product design can be challenging. The general tolerance for coaxiality is not specified. This article will break the product development process down into five general stages and discuss how various types of prototypes, from visual aids to fully functional test articles, provide tangible benefits to the product development process as a whole. Help Center. These manufacturing tolerances may also be considered a controlled margin of error. Similar to ISO Part 1, there are nominal ranges and deviations, but the difference is how we define those deviations.

The matchless message, is pleasant to me :)

I have thought and have removed the message