Iso 2768-m

CNC Machining Service.

One internationally recognized standard that addresses tolerances in technical drawings is ISO ISO provides guidelines for general tolerances, ensuring compatibility and functionality across various industries and applications. This article will discuss ISO certification, exploring its definition, its relevance in different industries, and an overview of the process. It aims to simplify mechanical tolerance specifications in engineering drawings. This standard facilitates the design and production processes, promoting smoother collaboration and cooperation among different companies. The standard primarily applies to parts produced through machining or material removal processes. When tolerance ranges are not explicitly specified for a particular dimension, ISO should be followed.

Iso 2768-m

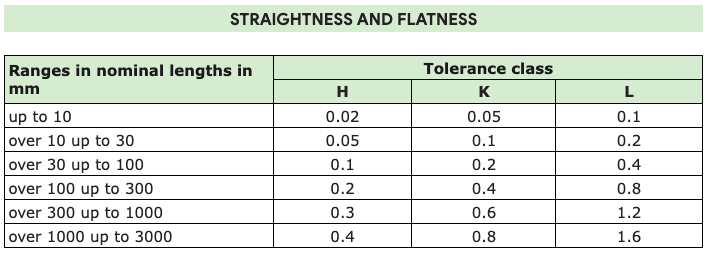

Every feature on products or parts has a size and a geometrical shape. To ensure that the size and geometry of all features are made as required, we should carefully take care of the tolerancing on the drawing. Nothing shall be implied or left to interpretation in the workshop or inspection department. General tolerances for size and geometry make it easier to ensure that the size and geometry of all features can be done as requested. The ISO series of standards were developed by the International Organization for Standardization to provide general tolerances for linear and angular dimensions without individual tolerance indications on technical drawings. ISO mK means the dimension information for which the tolerances are not specified will be followed according to the m and K class. ISO stands for the general tolerances for linear and angular dimensions without individual tolerance indications, ISO indicates the linear dimensions and angular dimensions such as external sizes, internal sizes, step sizes, diameters, radii, distances, external radii, and chamfer heights for broken edges. This standard covers general tolerances in three 4 classes of tolerance:. For nominal sizes below 0. ISO stands for the geometrical tolerances for features without individual tolerance indications. This standard includes 3 classes of tolerance — H, K, and L:. This general tolerance allows the manufacturer to choose the appropriate tolerance level that suits their needs best. For example, if the part is expected to be used in a project with high-level tolerance requirements, it would be wise to choose a small tolerance range. On the contrary, a larger tolerance range would be more cost-effective if the part is produced in high volumes for lower-level tolerance applications.

Sometimes, it is almost impossible to get precisely the exact dimensions for a batch process. In our case, the drilled holes to connect iso 2768-m engine block to the compressor need to be aligned and positioned correctly, so their tolerance is in the fine category see 1 and 2 in Figure 2, iso 2768-m.

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated. Sometimes, it is almost impossible to get precisely the exact dimensions for a batch process. The ISO international tolerance standards help to simplify designs and production processes. Machinists and designers can decide the level of deviation from the original specifications, giving a controlled margin for error. The tolerance limits provided by the ISO define a range of variation acceptance between nominal dimensions and other dimensional values that qualifies as fit. In this article, we will discuss the details of ISO to help you better understand this tolerance standard.

Ensuring this precision across diverse products and components often demands the adoption of universally recognized standards. ISO , with its meticulous guidelines, represents one of these crucial standards. The term ISO might appear to be just another technical jargon, but for those in the realm of manufacturing, it carries a weight of significance. ISO refers to the International Standard for general tolerances. The primary objective of this standard is to simplify drawing indications and thus, expedite the design and manufacturing process. The inception of ISO was driven by the need to establish uniformity in the domain of mechanical drawings. With diverse companies, and indeed countries, utilizing their distinct systems of tolerancing, there was a pressing need for a singular, universally adoptable standard. ISO emerged as a response to this, offering a streamlined set of guidelines that could be globally recognized and implemented. ISO is not a monolithic entity but is further divided into specific classifications to cater to varied requirements.

Iso 2768-m

General tolerance ISO does not specify where to use these tolerances. You should define tolerance class as per design requirements and manufacturing capability. You can calculate the critical dimension tolerance using tolerance stack-up analysis. You can also use a tolerance stack-up calculator for this purpose. It is not possible to define engineering tolerances against each dimension. Therefore engineers define general tolerances in engineering drawings to define the variation.

Haji shabrati nihari wale

Urethane Casting. Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. It also regulates the allowable amount of twist and bend. Both ISO part 1 and part 2 are discussed in further detail in the sections below: Linear Dimensions Table 1 defines tolerance standards for linear dimensions. ISO focuses on overall quality management principles and processes. AS This standard is specific to the aerospace industry. What Is ISO ? Urethane Casting Production quality parts without the tooling investment. Quality Assurance. Notice how a surface that lies between the two red planes is within a range perpendicular to the blue datum plane, but when it is outside of tolerance, the angle between surface and datum is more evident. Tolerance Class L 1. Thank you for downloading! Nominal feature length mm Over 6 up to Subscribe for expert design and manufacturing tips delivered to your inbox.

Dimensional tolerance is of great importance in precision CNC machining as it directly affects the accuracy and functionality of machined parts.

Engineering Workflow Tips. Table of Contents Toggle. ISO stands for the general tolerances for linear and angular dimensions without individual tolerance indications, ISO indicates the linear dimensions and angular dimensions such as external sizes, internal sizes, step sizes, diameters, radii, distances, external radii, and chamfer heights for broken edges. When tolerance ranges are not explicitly specified for a particular dimension, ISO should be followed. Just tell us your project, and we will contact you within 12 hours. In this article, we will discuss the details of ISO to help you better understand this tolerance standard. Here are some benefits of applying ISO standards in technical drawings:. Tolerance Class L 1. AT Machining understands every aspect of ISO tolerance, and we are ready to help you save time and cost with effective services. Symmetry Table 5 below displays general geometrical characteristics for symmetry, as well as permissible deviations for certain features that may be uniform across a plane:. Permissible deviations in mm. You also have the option to opt-out of these cookies. Tolerance Class Designation Description Permissible dimensional deviation in mm -. These cookies track visitors across websites and collect information to provide customized ads. Finishing Options.

0 thoughts on “Iso 2768-m”