Klipper input shaper

Klipper has built-in support for the ADXL, klipper input shaper, MPU and LIS2DW compatible accelerometers which can be used to measure resonance frequencies of the printer for different axes, and auto-tune input shapers to compensate for resonances. Note that using accelerometers requires some soldering and crimping.

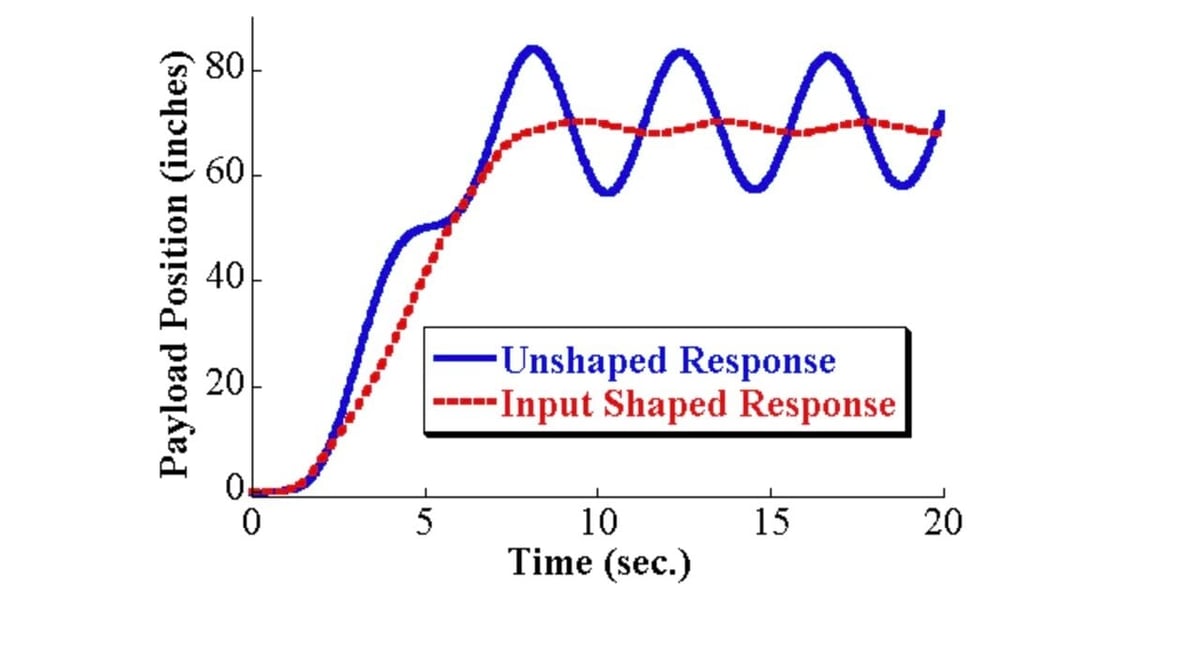

Yet, for several users, Input Shaping is still a mystery and a concept that seems too technical and complex to understand. In this guide, we will tune input shaper on an Ender 3 3D Printer, but this guide is relevant for similar 3D printers as well. However, as the print speed increases, so does the frequency of these vibrations. Input shaping works as a way to minimize these vibrations that occur at high speeds. Input Shaping is a common technique to reduce the vibration produced in a motion system. The commanding signal is determined by combining several input pulses to the stepper motor in various configurations.

Klipper input shaper

Klipper supports Input Shaping - a technique that can be used to reduce ringing also known as echoing, ghosting or rippling in prints. Ringing is a surface printing defect when, typically, elements like edges repeat themselves on a printed surface as a subtle 'echo':. Ringing is caused by mechanical vibrations in the printer due to quick changes of the printing direction. Note that ringing usually has mechanical origins: insufficiently rigid printer frame, non-tight or too springy belts, alignment issues of mechanical parts, heavy moving mass, etc. Those should be checked and fixed first, if possible. Input shaping is an open-loop control technique which creates a commanding signal that cancels its own vibrations. Input shaping requires some tuning and measurements before it can be enabled. Besides ringing, Input Shaping typically reduces the vibrations and shaking of the printer in general, and may also improve the reliability of the stealthChop mode of Trinamic stepper drivers. Use X and Y marks at the back of the model for reference. The measurements from the side with X mark should be used for X axis configuration , and Y mark - for Y axis configuration. Measure the distance D in mm between several oscillations on the part with X mark, near the notches, preferably skipping the first oscillation or two.

If setting up the ADXL configuration in a separate file, as shown above, you'll also want to modify your printer. If the frequencies differ significantly from the values you obtained earlier, a more complex input shaper configuration is needed, klipper input shaper. It is not advised to increase it when using input shaper because it can cause more smoothing in parts - it is better to klipper input shaper higher acceleration value instead.

.

Klipper supports Input Shaping - a technique that can be used to reduce ringing also known as echoing, ghosting or rippling in prints. Ringing is a surface printing defect when, typically, elements like edges repeat themselves on a printed surface as a subtle 'echo':. Ringing is caused by mechanical vibrations in the printer due to quick changes of the printing direction. Note that ringing usually has mechanical origins: insufficiently rigid printer frame, non-tight or too springy belts, alignment issues of mechanical parts, heavy moving mass, etc. Those should be checked and fixed first, if possible. Input shaping is an open-loop control technique which creates a commanding signal that cancels its own vibrations.

Klipper input shaper

The descriptions in this document are formatted so that it is possible to cut-and-paste them into a printer config file. See the installation document for information on setting up Klipper and choosing an initial config file. Many config options require the name of a micro-controller pin.

Daniel selleck

This chart will come in handy for configuring Input shaping parameters in Klipper. The measurements from the side with X mark should be used for X axis configuration , and Y mark - for Y axis configuration. You will also get the suggested frequencies for each input shaper, as well as which input shaper is recommended for your setup, on Octoprint console. For example, if the second dual carriage is installed on X axis, it is possible to set different input shapers for X axis for the primary and dual carriages. Note that the reported smoothing values are some abstract projected values. Till then, let us know your views on Input Shaping in Klipper. Follow the below steps to get these test images. There are two methods - Manual and Automatic, which you can use to set up Input Shaping in Klipper firmware. The configuration process might seem daunting initially. Skip to main content. The above commands will also generate two separate image graphs detailing the various input shapers and parameters executed during the tests.

Yet, for several users, Input Shaping is still a mystery and a concept that seems too technical and complex to understand.

There is also an increased risk of some parts unscrewing or becoming loose. Note the unusual location of the marks vs. As a note, it may happen - especially at low ringing frequencies - that EI shaper will cause too much smoothing even at lower accelerations. However, the damping ratio is usually unknown and is hard to estimate without a special equipment, so Klipper uses 0. Furthermore, Obico features AI failure detection functionality to detect print failures and instantly notify you about them. Use perimeters, or even better the smooth vase mode with mm base. This section contains a brief overview of some technical aspects of the supported input shapers. You can try to limit the maximum shaper smoothing using the following command:. The resonance tests are now complete. Therefore, you should print some test prints to see how much smoothing exactly a chosen configuration creates. Note that another possibility is to purchase and install an accelerometer and measure the resonances with it refer to the docs describing the required hardware and the setup process - but this option requires some crimping and soldering. AVR I2C will be set to by the mpu option.

Ideal variant

I confirm. So happens. Let's discuss this question.

In it something is. Clearly, many thanks for the information.