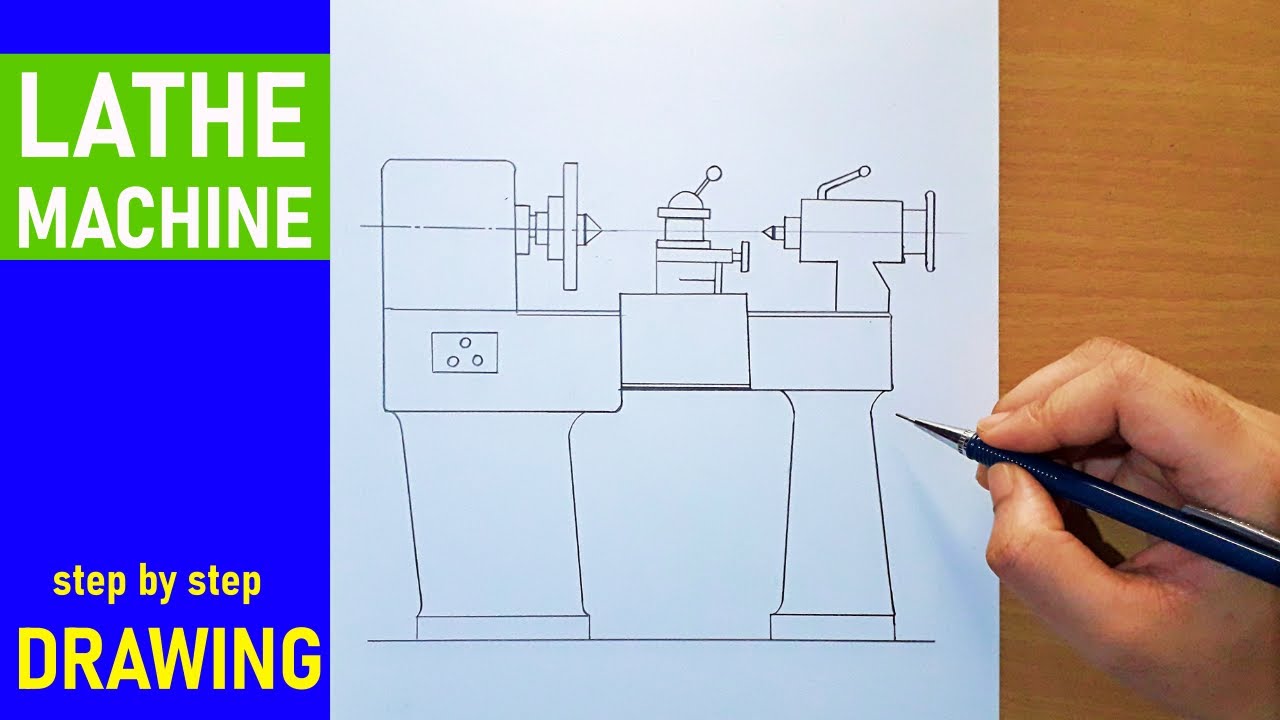

Lathe machine diagram easy

In the Mechanical Engineering field Lathe machine plays an important role in Manufacturing.

The Mechanical engineering stream has seen some tremendous machines invented and modified all these years. One of the remarkable machines that completely revolutionized the way we perform operations on metal or wood is the Lathe Machine. Lathe is a machine tool commonly used in all industrial applications. Now, a machine tool is power-driven and designed to move a sharp cutting tool against a rigidly held workpiece material or vice versa to remove material from the workpiece. In this article, we will discuss the definition, parts, working principle, and types of lathe machines. You will learn the operations that are performed on the machine in brief. A lathe machine is a machine tool that is used to remove unwanted material from a rotating workpiece in the form of chips.

Lathe machine diagram easy

The lathe machine is one of the most revolutionary inventions in mechanical engineering that lead everything to another level. The workpiece is connected to a rotating shaft and a cutting tool is used to remove materials from the rotating workpiece. In this article, you will learn about different parts of the lathe and their functions. The headstock of a lathe is the side where we fix the workpiece. The spindle, also known as workpiece spindles is used to provide rotational motion to the chuck and then to the workpiece. In a normal bench lathe, there are two spindles. One belongs to the headstock and the other belongs to the tailstock. So, each spindle is known as the headstock spindle and toolstock spindle. Chuck is a type of clamp that we use to hold the workpiece in radial symmetry. However, there are different mechanisms to clamp a workpiece in radial symmetry. As a result of that, there are several different chucks used in lathe machines. And those are as follows. As the name suggests, the speed selector is used to control the rotating speed of the workpiece. Since the spindle is directly connected to the chuck and the workpiece is directly connected to the chuck, the speed of the workpiece is the same as the spindle speed.

Dipak Umbardand July 30, It is so useful for us Thanks so much.

Working Principle : The lathe is a machine tool which holds the workpiece between two rigid and strong supports called centers or in a chuck or face plate which revolves. The cutting tool is rigidly held and supported in a tool post which is fed against the revolving work. The normal cutting operations are performed with the cutting tool fed either parallel or at right angles to the axis of the work. The cutting tool may also be fed at an angle relative to the axis of work for machining tapers and angles. Construction : The main parts of the lathe are the bed, headstock, quick changing gear box, carriage and tailstock. Bed : The bed is a heavy, rugged casting in which are mounted the working parts of the lathe. It carries the headstock and tail stock for supporting the workpiece and provides a base for the movement of carriage assembly which carries the tool.

The lathe machine is one of the most revolutionary inventions in mechanical engineering that lead everything to another level. The workpiece is connected to a rotating shaft and a cutting tool is used to remove materials from the rotating workpiece. In this article, you will learn about different parts of the lathe and their functions. The headstock of a lathe is the side where we fix the workpiece. The spindle, also known as workpiece spindles is used to provide rotational motion to the chuck and then to the workpiece. In a normal bench lathe, there are two spindles.

Lathe machine diagram easy

Lathe machines are probably the most common and important machine in a mechanical tool room. The figure highlights the main parts of a lathe machine. We will dive into each of them and understand their purpose and functions. The main parts of a lathe machine are:. The carriage of a lathe is a part that provides attachments whose function is to support, guide, and control the cutting tool. These are the main parts of the carriage of the lathe:. In the drilling operation that we perform on a lathe machine, the job rotates while the tool stays still.

Imperio railing systems

What is a Lathe Machine? Filling and Polishing. The process of knurling involves embossing a pattern, usually diamond-shaped, on the surface of the workpiece mounted on the lathe machine as shown in the image below. There is a fairly large variation in their design, construction and use. Now, a machine tool is power-driven and designed to move a sharp cutting tool against a rigidly held workpiece material or vice versa to remove material from the workpiece. Programs are fed into the computer system in this machine, which manages functions. Fig 5: Boring Operation Reaming The process of sizing and completing a hole that has already been drilled or bored is called reaming. Definition of Lathe Machine. The pointed end of it is placed touching the other end of the workpiece to avoid an abrupt stop in rotation and reduce friction. The knurling process is usually done to provide the workpiece with a good gripping surface. This can be done in several ways:.

Affiliate Disclaimer: We're a participate in the Amazon affiliate program. Therefore, we may collect a share of sales or other compensation from the links on this page, at no extra cost to you!

The process of reducing the overall length of the workpiece and producing a flat surface as a result is called facing operation. Moreover, the headstock has rotational motion and also the lead screw. Bcoz most of parts of machine are use to make on this machine….. Errors in measurement. Want to know more about this Super Coaching? Cutting Tool Holding device. Bench Lathe It is a compact lathe machine that is put on a workbench and consists of all the components of a speed lathe and an engine lathe. Refer to the lathe machine diagram below as you learn. Speed lathe machine. The feed rod is used to transfer power to the carriage just like in the lead screw. The turret lathe has a hexagonal turret instead of a tailstock. The pointed end of it is placed touching the other end of the workpiece to avoid an abrupt stop in rotation and reduce friction. Realted Posts.

0 thoughts on “Lathe machine diagram easy”