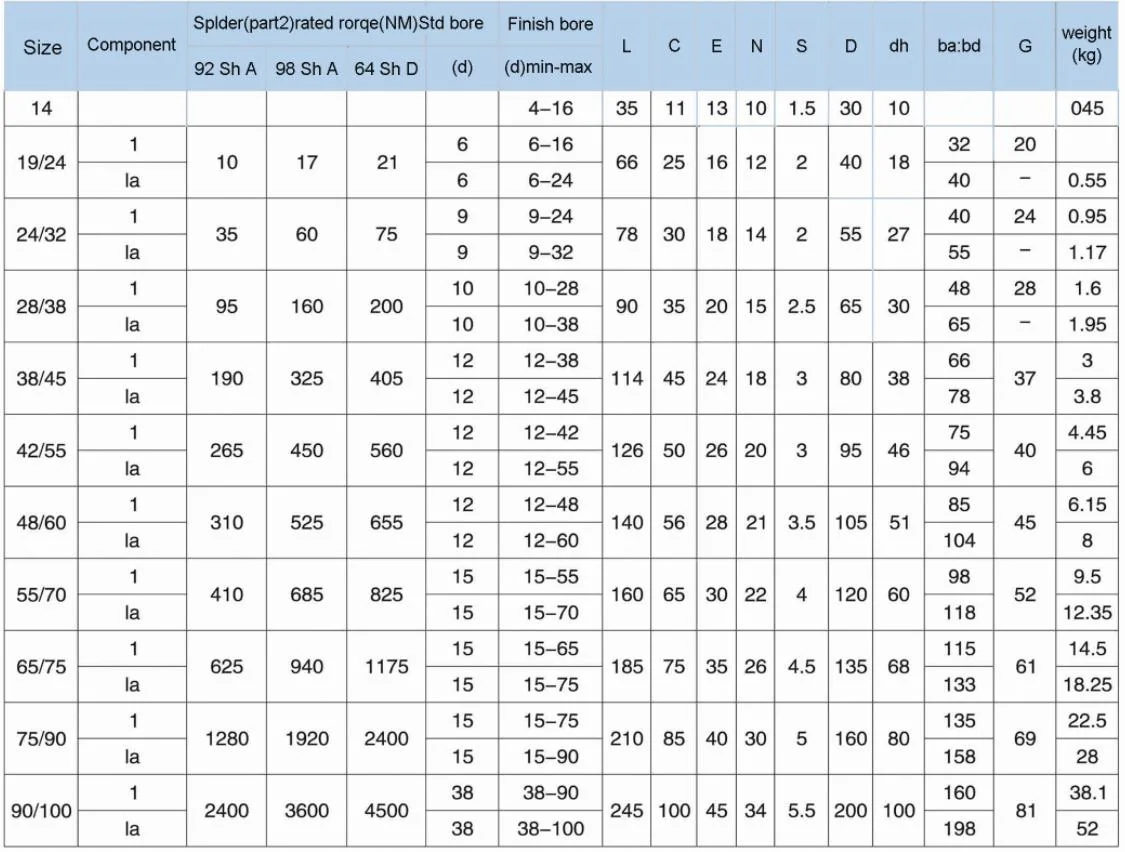

Lovejoy coupling size chart

The goal of this handbook is to assist you with the process of sorting out the myriad of coupling styles that exist to select the one best suited to your application. This handbook is not a textbook.

Safety Warning When using Lovejoy products, you must follow these instructions and take the following precautions. Failure to do so may cause the power transmission product to break and parts to be thrown with sufficient force to cause severe injury or death. Refer to this Lovejoy Catalog for proper selection, sizing, horsepower, torque range, and speed range of power transmission products, including elastomeric elements for couplings. Follow the installation instructions included with the product, and in the individual product catalogs for proper installation of power transmission These couplings require no lubrication and provide highly reliable service for light, medium, and heavy duty electrical motor and internal combustion power transmission applications. Lovejoy offers four types of elastomer designs to allow for additional flexibility in addressing specific application requirements. The load cushions are in sets of 6 to 14 pieces depending on coupling size.

Lovejoy coupling size chart

.

That is called a major diameter fit. High Speed Gear Couplings. It makes the assembly of the coupling to the shaft easier, and makes replacement of seals easier.

.

Jaw Type Couplings Catalog pdf. Stainless Steel Jaw Sell Sheet pdf. Jaw Coupling Selection Worksheet pdf. Urethane — Greater torque capability than NBR 1. Good resistance to oil and chemicals. Excellent resistance to oil and chemicals. Bronze — Rigid, porous oil-impregnated metal insert exclusively for low speed max RPM applications requiring high torque capabilities. Not affected by extreme temperatures, water, oil, or dirt. Note: In addition to solid center spiders most common , open center spiders are also available to allow shafts of the driver and driven to be positioned within a short distance. For additional documentation in PDF form , please download the Jaw Coupling catalog pdf or contact Lovejoy customer service.

Lovejoy coupling size chart

Each hub includes a set screw unless noted , which bites into your shaft to hold the coupling in place. A complete coupling consists of two hubs and one spider, or two hubs, one split spider, and one retaining ring all components sold separately. Twist-lock them in place using a retaining ring. Stainless steel hubs have excellent corrosion resistance. Buna - N spiders provide good vibration damping and chemical resistance. Hytrel spiders provide fair vibration damping and excellent chemical resistance. Polyurethane spiders and split spiders provide fair vibration damping and good chemical resistance. For technical drawings and 3-D models, click on a part number.

Swim spa backyard designs

The combination of molded sleeves and powdered metal pressed hubs are a very economical coupling combination. When the designer needs to span a long gap between driving and driven equipment as when reaching up to a big-diameter roll, removing a large piece of equipment from an on-line position, or extending through a wall or bulkhead a floating shaft is needed. There are several methods to fasten the hub to the shaft. Both toothed hubs fit inside the ends of a tubular sleeve that has matching gear teeth cut around its interior circumference, with each tooth extending axially the full length of the sleeve. These couplings have a very low torsional stiffness ratio, in the range of 1. When the temperature increases the coupling must be derated. RunRight by Lovejoy Catalog 68 Pages. One notable one is the grid coupling described in its own section of this handbook. To accomplish that, the hub keyway is cut to be in line with a tooth or a space. Lovejoy Composite Disc Couplings 8 Pages.

The goal of this handbook is to assist you with the process of sorting out the myriad of coupling styles that exist to select the one best suited to your application. This handbook is not a textbook.

The tooth strength is calculated as a bending moment at the root of the tooth, the shear strength at the pitch line, and the Hertzian loading at the contact surface. Safety Warning When using Lovejoy products, you must follow these instructions and take the following precautions. Balanced couplings may require weigh-balanced bolts. Gear couplings can be configured with only one flex plane, for applications where parallel misalignment capability is unwanted. The distance between shaft ends BSE will vary with different machine systems to accommodate design standards, product line alternatives,different motor frames and maintenance needs. If shafts are small, or not well supported, or bearings are not substantial enough, these reactionary loads can cause problems. Everything is built for speed, which means small, light and precise. Torque is transmitted from one shaft to the other through the compression of the elastomer between the driver hub jaws and the driven hub jaws. If the coupling fits the application but its standard off-the-shelf model is not rated for the RPM required, determine whether the coupling can be economically changed to bring it up to the necessary speed. Refiners, Jordan machines, and roll winders found in paper mills utilize this sliding capability.

In it something is. Earlier I thought differently, thanks for an explanation.