Mrp controller table in sap

This topic has been locked by an administrator and is no longer open for commenting. To continue this discussion, please ask a new question. Your daily dose of tech news, in brief. Welcome to the Snap!

The MRP controller is responsible for material requirements planning and material availability. They ensure that the materials required to manufacture finished products or superior assemblies are available on time. They evaluate the material requirements planning that generates receipts order proposals for customer requirements and the planned independent requirements of the finished products. As a result of these receipts, secondary requirements are created for the subordinate assembly or materials that must in turn be covered by receipts. Depending on the company structure, the MRP controller can be responsible for the material availability for the entire production chain of a product as well as for the material availability of certain production levels. They can use key figures such as range of coverage and exception messages to help them complete their tasks.

Mrp controller table in sap

.

Scheduling deviations, overall and detailed.

.

The MRP controller is responsible for material requirements planning and material availability. They ensure that the materials required to manufacture finished products or superior assemblies are available on time. They evaluate the material requirements planning that generates receipts order proposals for customer requirements and the planned independent requirements of the finished products. As a result of these receipts, secondary requirements are created for the subordinate assembly or materials that must in turn be covered by receipts. Depending on the company structure, the MRP controller can be responsible for the material availability for the entire production chain of a product as well as for the material availability of certain production levels. They can use key figures such as range of coverage and exception messages to help them complete their tasks.

Mrp controller table in sap

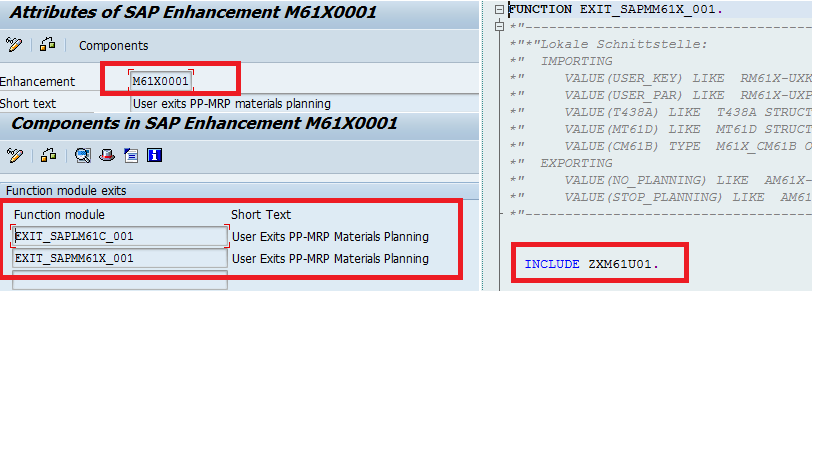

It represents the person, or group, that will be responsible of controlling the material workflow scheduling. There, the available entries will be displayed, or clicking on the New Entries button will allow the creation of a new one:. Enter all the mandatory details : Plant, code, description, business area, profit center, recipient type and recipient. The SAP MRP transactions will define for example which time is necessary to produce a chosen amount on time, and found out what could be missing, like some raw material stock, or other products based on their SAP material type and the production recipe. It can contain either fixed or default values, and using an existing MRP profile will facilitate the task of the material master creation, as some repetitive tasks might be avoided. The control code in Material master creation is a government code called HSN for Harmonized System of Nomenclature, a way to classify the commodities among countries. The material requirements planning controller is the physical person that will be responsible for following the planning of the material requirements among its usage within the organization.

Porno fnaf

You guys realize the original question was from , right? But it's the job of Functional Consultant Best regards Pankaj Thakkar flag Report. As a result of these receipts, secondary requirements are created for the subordinate assembly or materials that must in turn be covered by receipts. The MRP controller monitors stocks, carries out order and material analyses, operation and work center analyses, as well as quality analyses. The workbooks contain one or more queries that yield the relevant information. The MRP controller's tasks include: Executing and monitoring material requirements planning. Structure Tasks in the Business Information Warehouse The MRP controller monitors stocks, carries out order and material analyses, operation and work center analyses, as well as quality analyses. Today in History: February 23, - the discover Range of coverage finished products - quantity. It was created hastily just so I could make some posts, so the quality isn't the best. What food do you like that no Schedule and scrap deviation, order view. Consignment stock, receipts and issues.

.

Regards, flag Report. Welcome to the Snap! Area to Analyze Cluster. Range of coverage raw materials - value. Converting order proposals. What food do you like that no Schedule and lead time deviation, order view. Go through the following path Production They can use key figures such as range of coverage and exception messages to help them complete their tasks. Notification analysis - quality management. The following workbooks are available for the MRP controller: Area to Analyze Cluster Workbook Stocks Quantity-based warehouse stock Value-based warehouse stock Period-dependent requirements coverage Obsolete warehouse stock Range of coverage - quantity Range of coverage raw materials - quantity Range of coverage finished products - quantity Range of coverage raw materials - value Range of coverage - value Range of coverage - value Material stock and movements. Negative and positive schedule deviation, order view. Quantity, scrap and lead time deviation, order view. Login Join.

I am sorry, that has interfered... At me a similar situation. I invite to discussion. Write here or in PM.