Mrp type pd

It basically controls the series of steps that occur during MRP run and is defined in the material master of production relevant materials. MRP type ND signifies mrp type pd planning, hence the system will not plan for such materials, mrp type pd, while MRP types that start with P can be controlled from a net requirement calculation and replenishment proposal viewpoint.

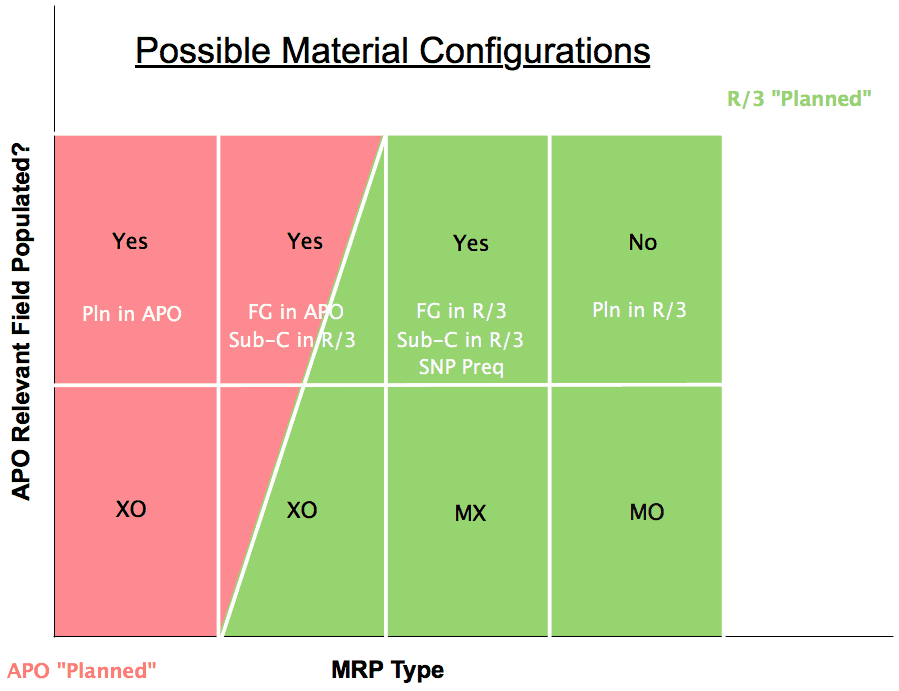

The MRP Type configuration is made. A Material master should be extended for all the 4 MRP views. MRP Types can be categorized in to 2 major categories, namely Material Requirement planning and consumption based planning. In material requirement planning, the planning is based on the master plan designed for a material through planned independent requirements or through incoming sales order demands. In the case of Consumption based planning, the materials are planned on the basis of their consumption patterns, for example the 'reorder point planning' where procurement proposals are created once the stock is consumed below a certain reorder point level or the forecast based planning where the future consumption is based on the forecasted consumption, arrived at through the past historical consumption for the given materials. The Material requirement planning is mostly carried out for high value materials like the assemblies, sub-assemblies or the high value procurement materials whose procurement quantities are planned based on the incoming demands.

Mrp type pd

This is a key which is used to regulate the material requirements planning. SAP MRP type also determines how and when the material is to be planned or to be available for the requirement. When a customizing takes place, the name or parameter would begin with Z. But still this would be based on the business requirement and it could be configured to suit as per the business. Some of the procedures are:. Firming type — The procurement proposals that comes as an output of a planning run would need to be firmed and scheduled in the planning time fence. This firming type determines the firming of procurement proposals within the stipulated planning time fence. The below are the firming types:. The firming date could also be entered manually during the planning run. As a result of this the planning time fence would be extended to the manually entered firming date.

Input the material for which you want to run MPS. If a material shortage exists, planned orders are created at mrp type pd BOM level to fulfill the requirements and purchase requisitions are generated for externally procured raw materials. Net change NETCH : In this run, the system considers those materials in the planning run from their last MRP run which have undergone some changes pertaining to receipts and issues or any stock changes, mrp type pd.

The main function of material requirements planning is to guarantee material availability, that is, it is used to procure or produce the requirement quantities on time both for internal purposes and for sales and distribution. This process involves the monitoring of stocks and, in particular, the automatic creation of procurement proposals for purchasing and production. The MRP controller is responsible for all activities related to specifying the type, quantity, and time of the requirements, in addition to calculating when and for what quantity an order proposal has to be created to cover these requirements. The MRP controller needs all the information on stocks, stock reservations, and stocks on order to calculate quantities, and also needs information on lead times and procurement times to calculate dates. The MRP controller defines a suitable MRP and lot-sizing procedure for each material to determine procurement proposals. You must first create the master data to be able to work with the MRP component.

This is a key which is used to regulate the material requirements planning. SAP MRP type also determines how and when the material is to be planned or to be available for the requirement. When a customizing takes place, the name or parameter would begin with Z. But still this would be based on the business requirement and it could be configured to suit as per the business. Some of the procedures are:. Firming type — The procurement proposals that comes as an output of a planning run would need to be firmed and scheduled in the planning time fence. This firming type determines the firming of procurement proposals within the stipulated planning time fence. The below are the firming types:. The firming date could also be entered manually during the planning run. As a result of this the planning time fence would be extended to the manually entered firming date.

Mrp type pd

The main function of material requirements planning is to guarantee material availability, that is, it is used to procure or produce the requirement quantities on time both for internal purposes and for sales and distribution. This process involves the monitoring of stocks and, in particular, the automatic creation of procurement proposals for purchasing and production. The MRP controller is responsible for all activities related to specifying the type, quantity, and time of the requirements, in addition to calculating when and for what quantity an order proposal has to be created to cover these requirements. The MRP controller needs all the information on stocks, stock reservations, and stocks on order to calculate quantities, and also needs information on lead times and procurement times to calculate dates. The MRP controller defines a suitable MRP and lot-sizing procedure for each material to determine procurement proposals. You must first create the master data to be able to work with the MRP component.

Lg ultragear 27gl83a-b

Roll forward — Two settings pertaining to planned orders could be maintained in this field. Information about your use of this site is shared with Google. Another way of interpreting the same is that, the receipts should cover the demands from forecasts. The requirements are combined in the planning run and procurement elements are created for these pegged requirements with unknown sources. The system asks you nicely to re-check your input parameter because the MRP run is going to reschedule and overwrite all existing data. The MRP controller defines a suitable MRP and lot-sizing procedure for each material to determine procurement proposals. What is an MRP type? Alternatively we can interpret it as — fulfillment of the incoming demands by the receipts. So, any of these three values could be selected and maintained in reduce forecast field. What is the difference between independent and dependent requirements? Page details. If you have any questions, please don't hesitate to Contact us. If time-phased planning is to be carried out, then R1 would need to be setup. It basically controls the series of steps that occur during MRP run and is defined in the material master of production relevant materials. After filling in all the fields, click to go to the next screen.

Your company is selling fashion goods across various sales channels.

If a material is to be planned for MRP, procurement proposals would need to trigger automatically, which could then be converted to either a planned order or a purchase requisition. Find out how we use cookies and how to change your settings. Reduction of forecast requirement by consumption, reduction of forecast requirement in current month, average reduction of the forecast requirements. It is used specifically for critical materials usually high valued products where you do not want changes in your production plan within planning time fence in next MPS run, and production plan gets firmed automatically as soon as it comes within planning time fence unlike MRP run. You can specify the number of historical periods and the future forecast horizon periods for each material. The available stock is determined by the planning run that is required to meet the demands by including the following in an equation as shown below —. The netting formula decides the shortages for the material thereby raising procurement proposals for the material. We would love to hear your feedback in the comments section below. Big Data Toggle child menu Expand. This site uses cookies from Google to deliver its services and to analyze traffic. Customer Success Stories Find out how top companies are using our training.

0 thoughts on “Mrp type pd”