Namur signal

We take a closer look at NAMUR sensors, providing insights into their namur signal and highlighting their significant roles across various industrial sectors, namur signal. Discover the underlying technology behind NAMUR sensors and their importance in different industries.

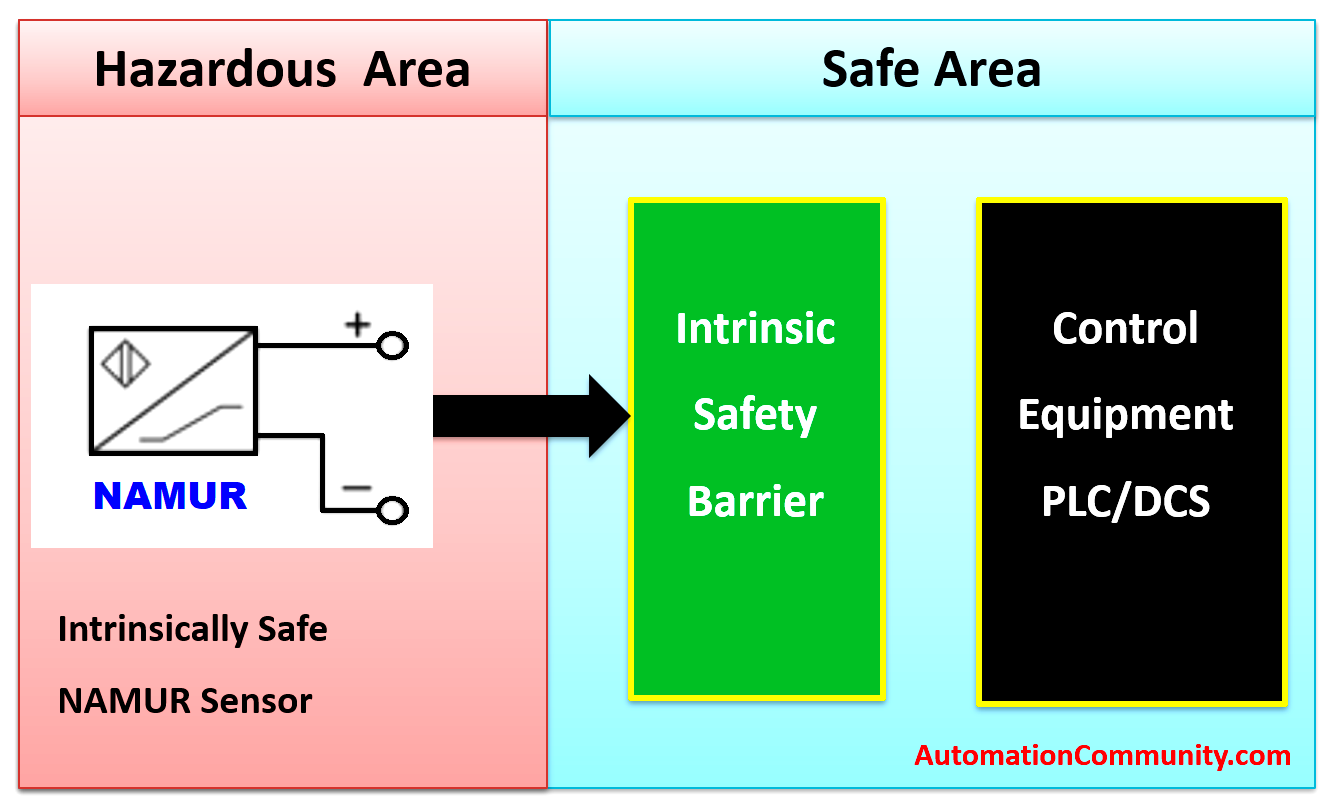

As can be seen, the connection has two wires only since these sensors have current and not voltage outputs. The power supply necessary for the functioning of the electronics inside the sensor is also conveyed through these two wires. In this case, as the distance S between the sensor and the object to be detected increases, there is an increase in the current in the sensor itself. Such a low output impedance is intended and aimed at avoiding, in the event of a fault, the creation of possible ignition sources in the event of a fault. Of course, for the correct use of devices with NAMUR output, it is necessary to use appropriately designed hardware.

Namur signal

One could be easily fooled by assuming that a NAMUR sensor is a typical proximity sensor because they look very much alike. But physical shape and appearance are the only characteristics they have in common. As illustrated in our animation, the proximity sensor acts just like a simple switch. When the target is away from the sensor, the switch is open. When the target is close to the sensor, the switch is closed. In most industrial applications today, a proximity sensor is not connected to an actual load resistance but is connected to an input of a PLC or DCS Digital Input Module. If you are interested in the exact description and its English translation, you can find it easily on the internet. The NAMUR proximity sensor has been in use for many years but like any electronic device, there are many different symbols in use. NAMUR proximity sensors are used in classified hazardous location areas that have explosive gas, dust, or fibers present. The NAMUR proximity sensor operates much like a typical proximity sensor but does not have an open or closed output condition. Instead, a NAMUR proximity sensor will produce two different and distinct current output levels corresponding to the target position. NAMUR proximity sensors limit current so that the current is not capable of causing ignition in hazardous atmospheres. Typical proximity sensors that continually make and break an output circuit could create sparks that could cause an explosion.

Related Articles. Read More Related Posts. They did this by forming working groups in four different areas to come namur signal with recommendations and guidelines to improve technology development and integration.

NAMUR is a type of sensor output that gives an on or off indication. I will go through some of them here. A NAMUR sensor is a non-amplified sensor that supplies two different signal levels depending upon switch state. These signal levels are low-level current. A NAMUR output sensor is required in installations where special safety measures are necessary locations with explosion hazard, or personal safety. Some of the specific types of proximity sensors that have NAMUR output are capacitive, inductive, magnetic, and photoelectric sensors.

One could be easily fooled by assuming that a NAMUR sensor is a typical proximity sensor because they look very much alike. But physical shape and appearance are the only characteristics they have in common. As illustrated in our animation, the proximity sensor acts just like a simple switch. When the target is away from the sensor, the switch is open. When the target is close to the sensor, the switch is closed. In most industrial applications today, a proximity sensor is not connected to an actual load resistance but is connected to an input of a PLC or DCS Digital Input Module. If you are interested in the exact description and its English translation, you can find it easily on the internet. The NAMUR proximity sensor has been in use for many years but like any electronic device, there are many different symbols in use. NAMUR proximity sensors are used in classified hazardous location areas that have explosive gas, dust, or fibers present.

Namur signal

As can be seen, the connection has two wires only since these sensors have current and not voltage outputs. The power supply necessary for the functioning of the electronics inside the sensor is also conveyed through these two wires. In this case, as the distance S between the sensor and the object to be detected increases, there is an increase in the current in the sensor itself. Such a low output impedance is intended and aimed at avoiding, in the event of a fault, the creation of possible ignition sources in the event of a fault. Of course, for the correct use of devices with NAMUR output, it is necessary to use appropriately designed hardware. The normative reference regarding the electrical output parameters of a NAMUR sensor is the EN Low-voltage switchgear and controlgear — part control circuit devices and switching elements — DC interface for proximity sensors and switching amplifiers NAMUR. NAMUR sensors are typically used in potentially explosive environments, as intrinsically safe devices: the energy that passes through them does not constitute an ignition hazard. If it is also necessary to have a certain degree of functional safety, if the sensor provides protection in this sense, safety hardware with NAMUR inputs is also available.

Under my ribs hurt right side

Typical proximity sensors that continually make and break an output circuit could create sparks that could cause an explosion. Control Valve Problem Causes Repeated Plant Trips In this article, you will learn the control valve problem that causes repeated plant trips and its root cause analysis. Related Articles. I will go through some of them here. These recommendations, identified by the 'NE' designation, aim to define equipment requirements, ensuring they are specifically tailored for applications and purposes. Standard three-wire proximity sensors use two wires for power and the third for the output, they have either a PNP or an NPN transistor output that switches the sensor if it detects a target. All courses. If you need to install a proximity sensor in a hazardous area that contains a potentially explosive atmosphere, you cannot use a standard three-wire sensor, because when the sensor switches to indicate a detection, the signal wire is connected or disconnected to the power supply, that action can generate an arc which can be a potential source of ignition. NAMUR sensors are essential for precise monitoring and control in various industrial applications. When the sensor detects a metal object or target, its impedance increases, and the electric current flowing through it drops to less than 1. NAMUR sensors are usually connected to external switch amplifiers that convert the current variation into a binary output signal. Industrial IoT.

We take a closer look at NAMUR sensors, providing insights into their functionality and highlighting their significant roles across various industrial sectors. Discover the underlying technology behind NAMUR sensors and their importance in different industries. Their initial focus was on setting standards for how different devices connect and work together, such as the mA technology and proximity switches.

January 11, PID Controller. I Agree. A mistake has occurred. See picture 5. When the target is close to the sensor, the switch is closed. Amplify Select Country. Machine Monitoring System in Nutshell The online machine monitoring system is used for rotating equipment to monitor and protect the motors from critical vibration and temperatures. These sensors are powered by a nominal 8. Add comment Cancel reply. Pramodh February 7, HMI Design. When the sensor detects a metal object or target, its impedance increases, and the electric current flowing through it drops to less than 1. When the target is away from the sensor, the switch is open.

0 thoughts on “Namur signal”