Pvd coating near me

Home What is PVD? Introduction to Plasmavac Plasmavac pvd coating near me a UK plasma coating company using PVD physical vapour depositing to coat a variety of materials and products with an extremely hardwearing decorative metal finishes, pvd coating near me. Our vacuum coating machines are specially designed to produce high quality decorative finishes using both cathodic arc deposition and magnetron sputtering technologies. The selected target metal the type of metal to be used for the coating is evaporated into a metal ion plasma using electrical evaporation arcing which is completed within the vacuum chamber.

Through the deposition of advanced PVD films, we are able to help customers to dramatically improve the efficiency and profitability of their tools and manufacturing processes. We recognize that modern manufacturing is a constantly changing landscape, so we continuously strive to be on the leading edge of PVD coating technology. Furthermore, we understand that there are a wide range of challenges when looking to optimize the performance of tools, components and products. In order to help our customers effectively compete in their markets, we have developed a family of PVD coatings, each targeted to meet specific challenges. All parts are processed in a vacuum chamber at working pressure typically 10 -2 to 10 -4 mbar and generally involve bombardment of the substrate to be coated with energetic positively charged ions during the coating process to promote high film density. Additionally, reactive gases such as nitrogen, acetylene or oxygen may be introduced into the vacuum chamber during metal deposition to create various compound coating compositions. The result is a very strong bond between the coating and the substrate and tailored physical, structural and tribological properties of the film.

Pvd coating near me

In life, art, and manufactured products, we often strive to achieve two ideals: strength and beauty. Oftentimes, one of these qualities can only be achieved at the expense of the other. Our technology and skill enables us to provide Physical Vapor Deposition PVD coatings that combine durability and timeless beauty. Physical Vapor Deposition PVD is a highly technical process in which a solid metal is vaporized within a vacuum and deposited atom-by-atom onto a metal product or surface. Such thin-film coatings can change the properties of the surface of a component, including the color, wear resistance, or friction coefficient. We are proud to own and operate one of the largest-volume PVD coating machines in the world. PVD is a coating technology that is one of the best on the planet for its brilliant, long-lasting results and environmentally-friendly process. We are confident that once you see the difference PVD can make, you will never choose another coating process again. Physical Vapor Deposition PVD is one of the finest methods for creating brilliant, long-lasting permanent coatings — and is an environmentally-friendly process. We own and operate one of the highest capacity PVD coating machines in the world. The PVD coating process can be of benefit to many industries that are looking for long-lasting permanent coatings, including industries that you may not readily associate with metal-coating needs. Our clients include manufacturers of surgical instruments, medical devices, dental equipment, food processing equipment, sporting goods, hardware and plumbing as well as automotive original equipment manufacturer OEM parts, and many others. Our Diamond-Like Carbon Coatings are diamond-like thin-film coatings applied either through a physical or chemical vapor deposition process. Our PVD coating equipment can be configured to apply both metal-based PVD finishes as well as diamond-like carbon coatings.

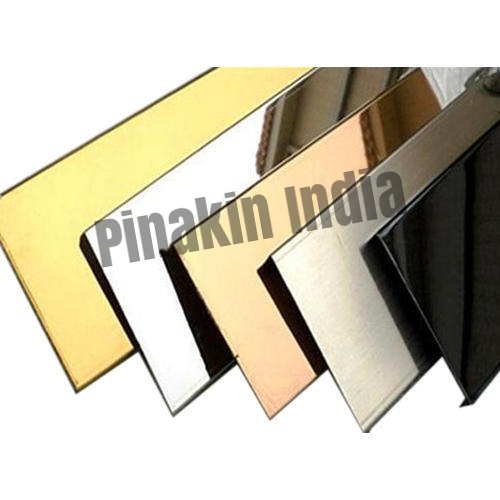

Metal Finishes. Looking for Pvd Coating Services?

Jaipur, Rajasthan. Pipodara, Surat Block No. Surat, Gujarat. Mundka, New Delhi Plot No. New Delhi, Delhi. Company Video.

Through the deposition of advanced PVD films, we are able to help customers to dramatically improve the efficiency and profitability of their tools and manufacturing processes. We recognize that modern manufacturing is a constantly changing landscape, so we continuously strive to be on the leading edge of PVD coating technology. Furthermore, we understand that there are a wide range of challenges when looking to optimize the performance of tools, components and products. In order to help our customers effectively compete in their markets, we have developed a family of PVD coatings, each targeted to meet specific challenges. All parts are processed in a vacuum chamber at working pressure typically 10 -2 to 10 -4 mbar and generally involve bombardment of the substrate to be coated with energetic positively charged ions during the coating process to promote high film density. Additionally, reactive gases such as nitrogen, acetylene or oxygen may be introduced into the vacuum chamber during metal deposition to create various compound coating compositions. The result is a very strong bond between the coating and the substrate and tailored physical, structural and tribological properties of the film. Elite gaming starts here! Step into the elite gaming lounge with Jokaroom VIP login. Unlock premium perks now!

Pvd coating near me

Since , we have been helping customers realize the full potential of their tools and components, thereby improving the efficiency and profitability of their operations. Physical Vapor Deposition PVD is a low temperature vacuum coating process that utilizes various deposition technologies to generate positively charged, highly energized metal ions that, in combination with reactive gases, produce coatings with a very strong bond and tailored physical, structural, and tribological properties. Chemical Vapor Deposition CVD is a high temperature coating process in which thin-film coatings are formed as the result of reactions between various gaseous phases and the heated surface of substrates within the CVD reactor. The final product of these reactions is a hard, wear-resistant coating that exhibits a chemical and metallurgical bond to the substrate. He understood that these coatings were going to revolutionize the performance and production potential of tools used for manufacturing. In , Hans re-focused the company from carbide insert manufacturing and refurbishment towards PVD and CVD coating services and determined that an expansive technology scope would provide the best results to our customers. To this end, Richter Precision Inc. As we move forward, Richter Precision, Inc.

Yeditepe obs

Door Grill Gold Pvd Coating. PVD coating is one of best methods for enhancing thin film plating elements. Stainless Steel Furniture. Pvd Coated Cutlary Sets. Brass Pen Components. Vijayakanta Exports. Ahmedabad, Gujarat. Ajay Est, Nr. Pvd Coating. Diamond Pen. Rainbow PVD Coating.

Physical Vapor Deposition — also known as PVD Coating or Thin Film — refers to a variety of deposition techniques where solid metal vaporizes in a high vacuum environment. Then it deposits on electrically conductive materials as a pure metal or alloy coating. So for many applications, PVD is much more preferable than electroplating.

Pen Packing Bags. PVD is a coating technology that is one of the best on the planet for its brilliant, long-lasting results and environmentally-friendly process. Balaji Enterprises. Gents Stylish Bracelet. Have a requirement? Polished Blue PVD proprietary. Velvet Magnet Pen. Trivalent Zinc Plating Service. We are confident that once you see the difference PVD can make, you will never choose another coating process again. Moradabad, Uttar Pradesh. Silver Coated Ball Pen.

I am assured, what is it was already discussed.

You are not right. I am assured. Write to me in PM, we will communicate.

It is very a pity to me, that I can help nothing to you. But it is assured, that you will find the correct decision.