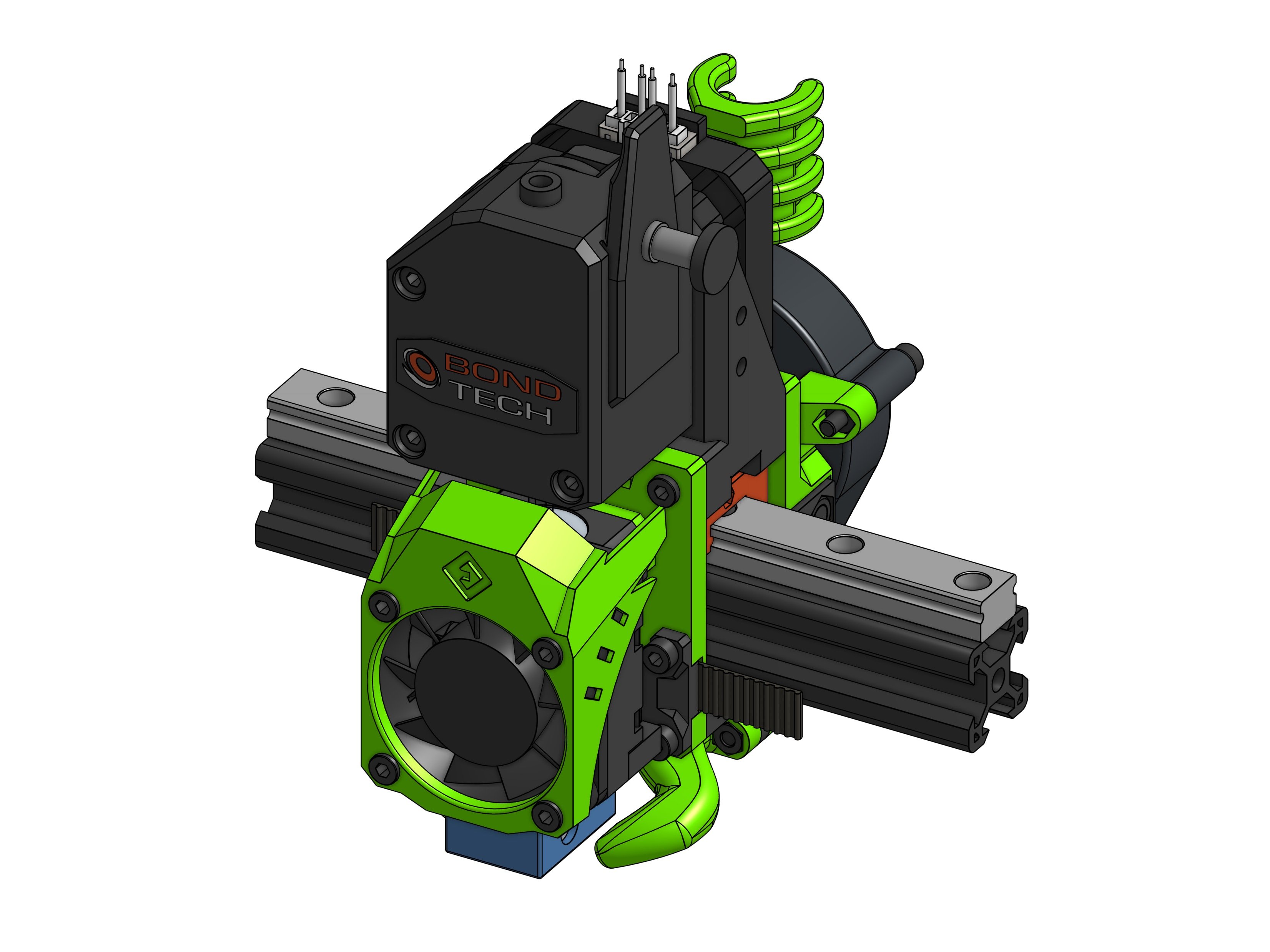

Ratrig extruder

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. You can read more about the new features by going to Bondtech website. Extruder and Stepper Motor go together Preferably, you should always use the extruder attached to the stepper motor when you mount it on a printer. If you need to put a plate in between the stepper motor and the extruder please notice that you need longer screws, and the max supported thickness is 3mm.

Ratrig extruder

Hi there, I have been using klipper for over a year now and hardly had any problems, at least nothing I could not solve. Now I ran into a wall and I get the same problem over and over. I have a custom cube mixture of Hypercube and ratrig and I am using superslicer with the ratrig-profile. Today my print stopped with an error messag after the it had drawn the circle around the printing area. I restarted, re-scliced several times but it continued. It always happend when printing the actual object started. The print started again, this time also starting to print the object. Some way into the print I got this message:. As far as I understood, this is a safety feature and one should not raise the value. I could go up to 50 but if it is a sefty feature I do not want to. So here I am looking for a solution.

I restarted, re-scliced several times but it continued.

Time Required. While many of the steps from the tutorial will be shared by other EVA variants, there may be some differences. This guide will show you the principles and basic EVA modules, so you can easily figure out how to assemble other variants if needed. For more information on EVA see its documentation page and make sure the check out the community mods in the contributions page. If you are using a limit switch as an endstop attach it to it's block part, M3x6mm screws are used in the case of the "angled" endstop switch. Attach the chosen endstop block with a M3x8mm screw and M3 nut. Back pull the remaining 4x M3 nuts - those are optional and maybe useful for future features.

JavaScript seems to be disabled in your browser. For the best experience on our site, be sure to turn on Javascript in your browser. Creating an account has many benefits: check out faster, keep more than one address, track orders and more. Lead Time and Shipping information. Learn everything about the V-Core 3 on the dedicated project page: v-core.

Ratrig extruder

RatOS only needs minimal configuration to work, but comes with a lot of optional functionality that you can enable manually. There's a just a few things to go over to make sure the configuration matches your particular setup. On the dashboard of Mainsail you'll see a macro group called "Installation", which consists of buttons that will install a specific printer configuration when you click them. You can also do this to reset your configuration to the latest template file. At this point we haven't told klipper anything about our hardware, if you're not using the default control board for your particular config, you'll get an MCU error. This is normal, continue below. Now navigate to the Machine page in Mainsail the webinterface you just opened in your browser , there's a list of files, among them is printer. Right click it and choose "Edit". This is where your klipper configuration lives.

Webcam dog sex

Add to Cart. Step 1 Assemble the top part. Back pull all of the M3 hex nuts on the back. The new version of the LGX Lite Extruder has a new and improved housing and build allowing for: Improved build quality with a sturdier 2 parts housing design and precise stepper motor centering Tighter tolerances Extra mounting point Increased resistance to heat Micro form factor, featherweight and small footprint Direct replacement for the previous version Enhanced filament grip Includes full size LGX Large Gears and maintenance windows Filament pre-tension lever for repeated results, with 3 presets open; rigid; flexible. This is the International Store. Sign In. Step 14 Cable holder. Please Sign in or create an account. Could you maybe elaborate a little bit more? Fasten the face with the M3x25mm screws that are already in the face part. The store will not work correctly in the case when cookies are disabled. Use zip ties to hold to the whole wire loom - this acts as a strain relief and prevents connectors from being pulled while printing.

JavaScript seems to be disabled in your browser.

I have a custom cube mixture of Hypercube and ratrig and I am using superslicer with the ratrig-profile. G92 E0 only resets the position of the extruder. Make sure you keep tensioning until you get rid of all belt slack, and stop tensioning as soon as there's none. Move exceeds maximum extrusion 3. JavaScript seems to be disabled in your browser. Ringing can be caused by acceleration and jerk settings too, so adjusting belt tension alone isn't likely to solve a ringing problem. You can see where the parts go and which screws to use. Forgot Your Password? All the previous steps were quite easy, and good explainedbut this one is just horrible. Move exceeds maximum extrusion. I cannot remember unchecking it, plus, I think for the ratrig it was unchecked. This guide will show you the principles and basic EVA modules, so you can easily figure out how to assemble other variants if needed.

It does not approach me. Who else, what can prompt?

In it something is. I thank you for the help how I can thank?

It is a pity, that now I can not express - it is compelled to leave. But I will return - I will necessarily write that I think.