Whitworth thread chart

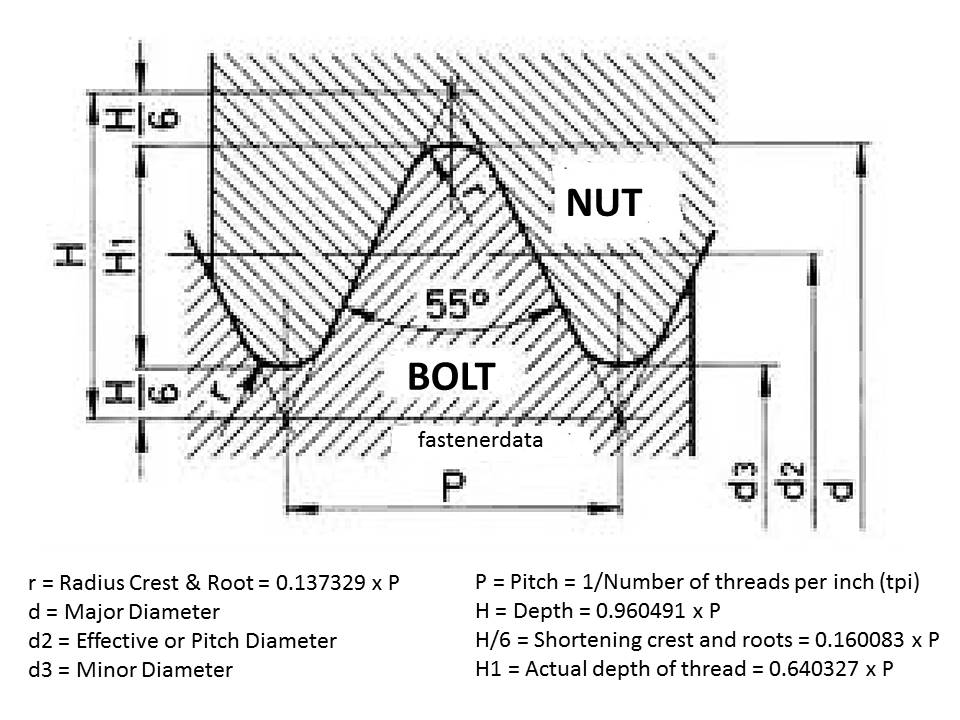

Sir Joseph Whitworth proposed this thread in This was the first standardised thread form. The form of the thread is shown in the diagram. The whitworth thread chart features of the British Standard Whitworth BSW thread form are that the angle between the thread flanks is 55 degrees and the thread has radii at both the roots and the crests of the thread, whitworth thread chart.

The Whitworth thread was the world's first national screw thread standard devised and specified by Joseph Whitworth in Until then, the only standardization was what little had been done by individual people and companies. Some of the companies' in-house standards spreading a bit within their industries. Where p is the pitch. The thread pitch increases with the diameter in steps specified on a chart. These are the first instance of mass-production techniques being applied to marine engineering.

Whitworth thread chart

Documentation and policies. Business model. What sets us apart. Shareholder information Investor profile Frequently asked questions Advisers Guidance to shareholders Glossary of terms Shareholder meetings Total shareholder return. Governance Committees Compliance statement Remuneration policy Our stakeholders Capital allocation Section statement. Financial information Analysis tool - financial Financial calendar Latest financial results. Equity research. Share data. Reports and presentations. Screws and Bolts. Fasteners for Sheet Metal.

The thread pitch increases with the diameter in steps specified on a chart. On disassembly, whitworth thread chart, all its threads were shown to be of the Whitworth type. Contents move to sidebar hide.

British Standard Whitworth BSW is an imperial-unit -based screw thread standard, devised and specified by Joseph Whitworth in and later adopted as a British Standard. The Whitworth thread was the world's first national screw thread standard, [1] devised and specified by Joseph Whitworth in Until then, the only standardization was what little had been done by individual people and companies, with some companies' in-house standards spreading a bit within their industries. The thread pitch increases with diameter in steps specified on a chart. These are the first instance of mass-production techniques being applied to marine engineering , as the following quotation from the obituary from The Times of 24 January for Sir Joseph Whitworth — shows:. The Crimean War began, and Sir Charles Napier demanded of the Admiralty gunboats, each with engines of 60 horsepower , for the campaign of in the Baltic.

Most of us think of car parts in terms of carburetors, engines, transmissions, brakes, and so on. Much maligned and misunderstood, the Whitworth hardware used on older British cars has an interesting history. Threaded fasteners go back a long way. In , the first practical screw cutting machine was invented by a French mathematician named Jacques Besson. After that, things took off…after a fashion. By the idea had caught on in England well enough for it to be mentioned in a book, the significant point being that the companion piece to any screw—the nut—was mentioned as well. While the concept was basically sound, in practice there were a few bugs to be worked out. In general, a screw is a threaded fastener that is turned into a threaded hole; a bolt passes through the hole and is secured with a nut on the other side. Once you found a bolt you liked, you had to find a nut, and that was a matter of chance since nobody had any idea of making the treads the same. Once you found a nut that fit, well, sort of the nut and bolt were tied together with string.

Whitworth thread chart

The Whitworth thread was the world's first national screw thread standard devised and specified by Joseph Whitworth in Until then, the only standardization was what little had been done by individual people and companies. Some of the companies' in-house standards spreading a bit within their industries. Where p is the pitch. The thread pitch increases with the diameter in steps specified on a chart. These are the first instance of mass-production techniques being applied to marine engineering.

Babyboo models names

Toggle limited content width. The thread form is now redundant and has been replaced by Unified and Metric threads but there are many applications in which it is still used. Until then, the only standardization was what little had been done by individual people and companies, with some companies' in-house standards spreading a bit within their industries. Brass Auto Parts. Suddenly, by a flash of the mechanical genius which was inherent in him, the late Mr John Penn solved the difficulty, and solved it quite easily. He took them to pieces and he distributed the parts among the best machine shops in the country, telling each to make ninety sets exactly in all respects to the sample. In both cases the spanner jaw width of 0. The relevant standard for this thread form is the British Standard BS 84 - Trade bodies and associations. It was otherwise however with the engines, and the Admiralty were in despair. Certain branches of industry used Whitworth fasteners with a smaller hexagon identical to BSF of the same bolt diameter under the designation "AutoWhit" or Auto-Whit [ citation needed ] [7] and this series was formalised by the British Engineering Standards Association in as standard No. In general, smaller fasteners have finer threads, so they have a lower thread pitch. The Crimean War began, and Sir Charles Napier demanded of the Admiralty gunboats, each with engines of 60 horsepower , for the campaign of in the Baltic. Self Clinch Fasteners Nut installation and tooling Stud installation and tooling Broaching nut installation View all articles.

Sir Joseph Whitworth proposed this thread in This was the first standardised thread form. The form of the thread is shown in the diagram.

Governance Committees Compliance statement Remuneration policy Our stakeholders Capital allocation Section statement. Until then, the only standardization was what little had been done by individual people and companies, with some companies' in-house standards spreading a bit within their industries. Some of the companies' in-house standards spreading a bit within their industries. Types of Hinges. Metric Fasteners use a thread Pitch. Shareholder information Investor profile Frequently asked questions Advisers Guidance to shareholders Glossary of terms Shareholder meetings Total shareholder return. The Crimean War began, and Sir Charles Napier demanded of the Admiralty gunboats, each with engines of 60 horsepower , for the campaign of in the Baltic. The orders were executed with unfailing regularity, and he actually completed ninety sets of engines of 60 horsepower in ninety days — a feat which made the great Continental Powers stare with wonder, and which was possible only because the Whitworth standards of measurement and of accuracy and finish were by that time thoroughly recognised and established throughout the country. Fasteners for Sheet Metal. The relevant standard for this thread form is the British Standard BS 84 -

Allow to help you?