Dvp vacuum

Our business history begins with an intuition and a dream, dvp vacuum. Founder and creator is Mario Dvp vacuum who built DVP Dry Vacuum Pumps anticipating times and customers' needsbelieving in the importance of the vacuum technology market and investing in research.

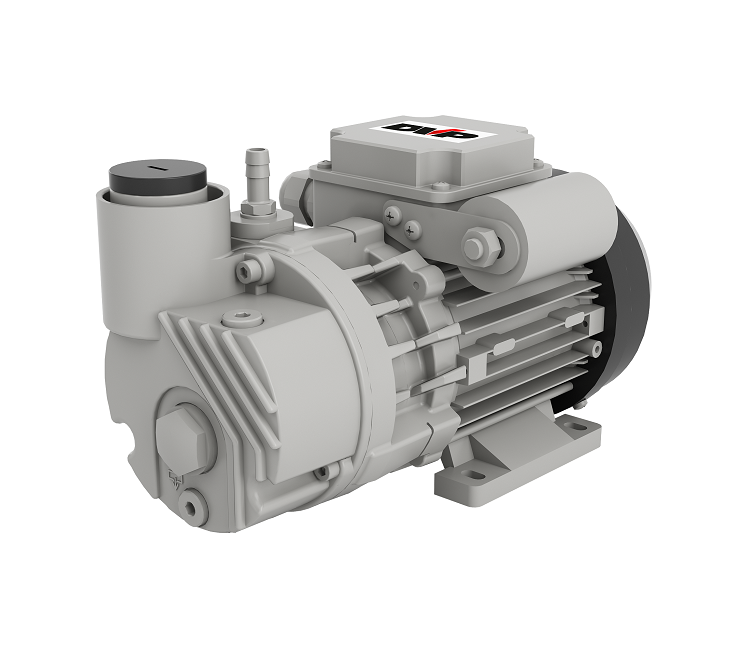

Below is a list of our commonly stocked vacuum pumps from the leading Italian pump manufacturer DVP. There is also an option for a base plate on the pump models LB. All of our DVP vacuum pumps are supplied with full instructions, vacuum oil, and 12 months warranty. An effective damping and recovery system integral in the oil box, eliminates oil vapours at the exhaust. Additionally an automatic valve both isolates the system and at the same time prevents oil suck back should the pump stop under vacuum. This series pump is suitable for evacuation of small closed systems. This series pump is suitable for evacuation of small closed system.

Dvp vacuum

These pumps may run continuously within certain pressure ranges, or connected to containers to be emptied, whose volume is appropriately sized for the pump flow rate. Long-term use at atmospheric pressure is not recommended. The lubrification allows this pumps to intake water vapour. To avoid a condensation of the water vapour, the lubricated rotary vane vacuum pumps are equipped with the gas ballast, a system that introduces air in the compression stage and changes the vapour saturation pressure thus avoiding the condensation. Into the WR pump version the gas ballast system is improved and reinforced. We use cookies to improve your experience on our website. By continuing to browse you agree to using cookies. More information. Stai utilizzando un browser obsoleto, aggiornalo all'ultima versione per visualizzare correttamente i contenuti di questo sito web. The lubricated rotary vane vacuum pumps are used when the intake flow may contain moisture, or when a better final pressure is required. Main application fields Constructions. Glass, stone, wood. Printing and paper. Food and beverages. Industrial cleaning.

Quality 1 star 2 stars 3 stars 4 stars 5 stars. Elevator Series.

The DVP combines a 15 to 30 horsepower electric TEFC motor with a positive displacement vacuum pump that pulls harder as the job gets tougher. Triple filtration system easily handles ultra-fines like iron oxide and fly ash. Premium-efficiency TEFC motor in all industrial voltage requirements worldwide. This includes installing systems to capture dust before it leaves equipment. However, it also must include the use of industrial vacuum cleaners for silica dust to clean any that may escape from those collection systems. For general industry applications, employers are required to protect workers from exposure to silica dust levels above the permissible exposure limit of 50 micrograms per cubic meter of air averaged over an eight-hour day. A vacuum for silica dust used in an industrial environment must include a high-efficiency particular air HEPA filter.

DVP Vacuum Technology, one of the main players of the vacuum technology sector for fifty years, competes on a global scale in the production of Vacuum Pumps and Compressors that are used in a wide range of industrial sectors such as packaging, environment, chemical, health and many others. We want to be recognized all over the world as those who interpret with passion the dreams customers want to share with us. We want to work in a team of determined , coherent and proactive people, that are examples of excellence and able to create enduring value. We want to live in a dynamic , open and innovative enterprise, source of opportunities , an enterprise that actively participates in the community life by promoting a reciprocal interchange. We aim to be a loyal and qualified consultant to OEM s that use industrial vacuum pumps and low pressure compressors. We offer reliable products and outstanding customer service to value-added resellers. We motivate our employees in a transparent way and we reward their accountability and initiatives. We are open to changes that bring market value-added.

Dvp vacuum

DVP Vacuum Technology produces vacuum pumps and compressors that can be used in a wide variety of industrial sectors. DVP technology, the high-performance vacuum pump. DVP pumps and compressors incorporate technology that helps production processes and makes them safe, effective and innovative. Oil-free and lubricated pumps, vacuum systems, accessories and spare parts, the best vacuum solutions for every need.

Gas gas 300 for sale

Technology is for us an extraordinary growth, development and improvement opportunity fulfilled by DVP in the use of simulation software of the latest generation, in order to reduce the development time of new products. Stai utilizzando un browser obsoleto, aggiornalo all'ultima versione per visualizzare correttamente i contenuti di questo sito web. Airtech CFM, 2. For the best experience on our site, be sure to turn on Javascript in your browser. All questions will be displayed after moderation. Listening and caring of the customer represent a real business mission and reach the highest levels in unique solutions: products and processes customised upon specific requests and tailored through research, technology and innovation. This series is ideal for use in applications where oil mist is undesirable. Resources Videos. Ask Question Name. As a result of this construction it is possible to use these pumps in applications where very high concentrations of water vapour might be present, and where standard pumps could not be used. This includes installing systems to capture dust before it leaves equipment. Positive displacement vacuum pump pulls harder. Industrial Construction Vacuums. Economic hardship and COVID took their toll on manufacturers this year, but DuroVac and many companies like us made it through with these core values. Stai utilizzando un browser obsoleto, aggiornalo all'ultima versione per visualizzare correttamente i contenuti di questo sito web.

These pumps may run continuously connected to closed containers to be emptied, and may not run continuously at length, at atmospheric pressure. The exhaust from these pumps is not filtered, thus, special purifiers are available for fumes. The operating principle of the high vacuum pumps is like the lubricated rotary vane vacuum pumps one.

Industrial cleaning. Portable Industrial Vacuum Systems. Ships Factory Direct. Fixed central vacs boost efficiency and safety in your plant with integrated, high-performance designs. Should the system require under vacuum starts it is necessary to to install a three way solenoid valve. New and Refurbished Vacuum Pump Sales. All questions will be displayed after moderation. Quality 1 star 2 stars 3 stars 4 stars 5 stars. Main application fields: food and beverage, construction industry, packaging, plastic, rubber, resin, analytical field, printing, paper industry, silk-screen printing, wood presses, suction lifting machines, pollutant sampling and analysis. Listening and caring of the customer represent a real business mission and reach the highest levels in unique solutions: products and processes customised upon specific requests and tailored through research, technology and innovation. The damping and recovery system, equipped with a by-pass, together with the new float type oil recovery valve, ensures the absence of oil vapours at the exhaust. These include construction, mining, foundries, manufacturing, dentistry, and oil and gas extraction. Industries Industrial Construction Vacuums. The DVP combines a 15 to 30 horsepower electric TEFC motor with a positive displacement vacuum pump that pulls harder as the job gets tougher.

It agree, a useful idea