Print in place

Great trend in 3D printing for several years, "Print-in-Place" or printing in print in place no support has revolutionized 3D modeling for 3D printing. Indeed, 3D files are now easily printable without support and are usable and sometimes even articulated when printing.

Pop Culture. Trending Searches. Trending Tags. Quick Links. Support Creators. Download Thangs.

Print in place

By latreides July 20, in Improve your 3D prints. I have been printing for awhile now, and I have never managed to get a "print in place" print to work correctly. What I mean is that any print that has movable parts that are intended to be printed as a single unit, never actually move. The parts are welded to each other. This happens no matter what slicer I use Cura or S3D and no matter what print material or brand I use. Additionally and probably caused by the same issue , any time I print a part that should fit in another part with small tolerances , it never fits. I understand that there is expansion and shrinkage in 3d printing, and the various reasons that the occurs, but clearly other people have managed to get these prints to work just fine. I have not managed with the things I downloaded. Some of the things they say are print in place are not that well made. I use the 0. They are all parts that dozens of other people report perfect success with. I have printed a few items both downloaded and my own design. I am planning on printing a similar item but 2 colors on UM3 tho i havent decided on what to print more like I am lazy of design at this time? The key problem here is tolerance and clearance for printers are different. My FF requires around 0.

Tolerances are crucial when 3D printing print-in-place parts.

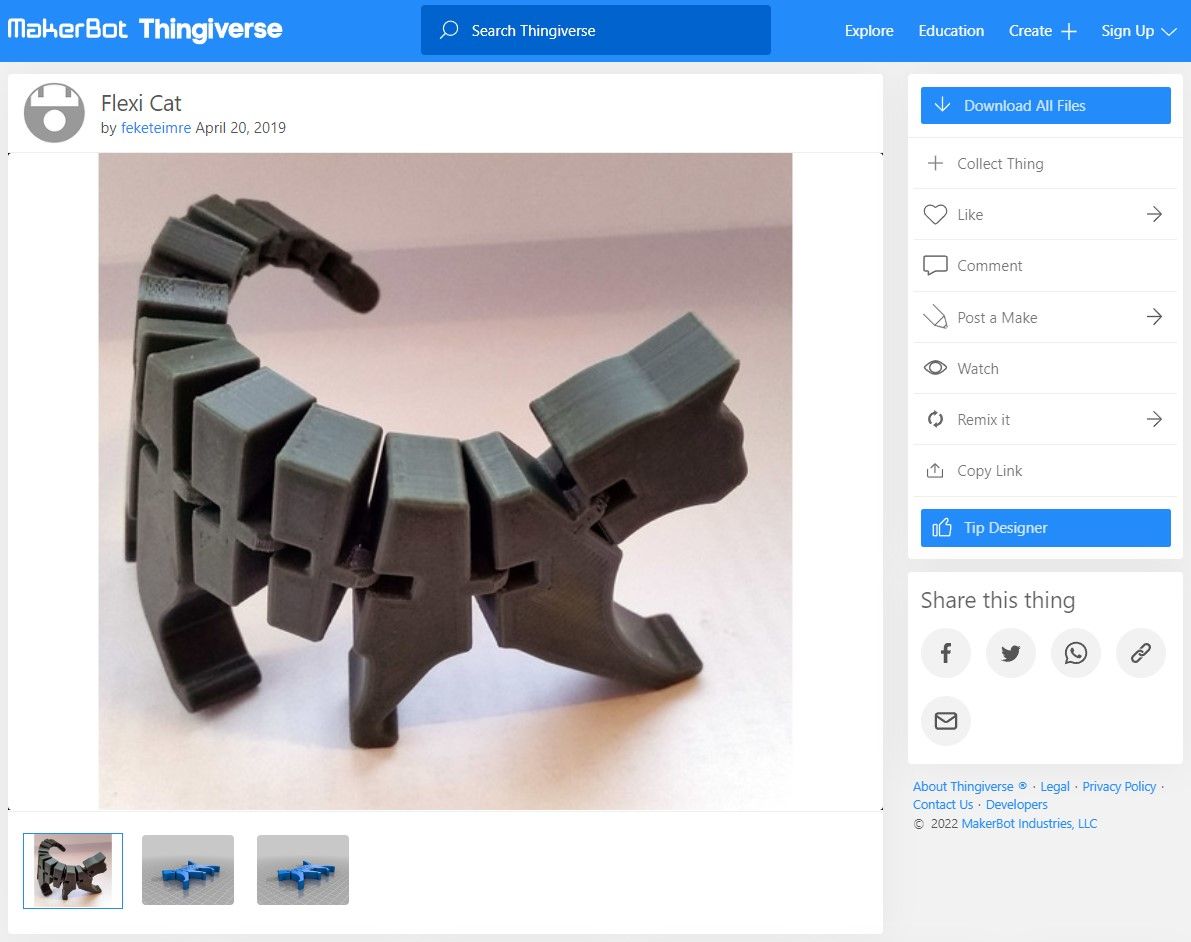

Print-in-place 3D printable models are objects with moveable parts that can be printed as a single piece. There are loads of examples of excellent print-in-place 3D printables around the web. You can find a collection of free print-in-place files below, all of which provide a good starting point for those getting into this type of printing. But before we dive in, let's make sure your printer is configured properly. Print-in-place parts make it easy to create mechanisms with moving parts, but you have to tune your 3D printer settings for the best results.

Tensegrity models, that are popular in 3D printing, can be used both for decorative and functional purposes. Tensegrity, a portmanteau of tension and integrity, describes a system where two or more components are under compression inside a network of continuous tension. It is easy to see that 3d printing would be great for printing the two main parts of a tensegrity table to which wire or string could be added post print, and 3d-print designers have created some beautiful models using this approach. I wanted to take it one step further and design a completely 3D printed print-in-place tensegrity structure. A tensegrity where the strings were single extruded lines of filament printed into, rather than glued or tied onto, the model. To design a print-in-place tensegrity structure we need to look at specific 3d printing considerations as well as the design of the structure in more general terms. The most important element of any tensegrity design is the shape of the two or more parts and the relationship between them. The parts need to overlap vertically and horizontally to provide positions where the two types of strings top to bottom, bottom to top can be anchored. A C-shape, rounded or squared off, is the simplest way to achieve this but we can also use a V shape and, of course, we can add design features around these core shapes.

Print in place

Learn more about the formats. The only thing to do after printing, is to cut one small support on each of the doors. To see exactly where to cut, please have a look at the pictures above. I highly recommend to spray some kind of lubricant between the moving parts in order to reduce friction, if the mechanism is too stiff. However, if the printer is well dialed in and you get the tolerances right, it works just fine without any post processing or lubricant. There is also a testprint included to try out the tolerances of the mechanism prior to printing the whole box.

Hello kitty wall paper

At its default scale, this tiny artillery piece can fire pieces of paper, plastic, and other debris more than two meters. FotisMint Moon Dragon Bust. Predator Action Pliers Free. Support Creators. The ones with telescoping blades that extend with a flick of your wrist. Sign In Sign Up. Maybe your over extruding, to hot nozzle or to fast printing. Exclusive Exclusive. Sign In Now. Print-in-Place" files often contain little surprises. Picture the light saber toys you saw as a child. These print-in-place action pliers are made to be 3D printed without supports or other additions and are ready to be used as soon as the print is over. Download Thangs. Indeed, 3D files are now easily printable without support and are usable and sometimes even articulated when printing.

Flexi Factory. Please enter the code below.

Those are the things I can think of. Downloads Date Likes. Hammerhead Shark Bones. Keep this in mind no matter the type of printer you use. Thick layers will reduce accuracy, as well as printing fast. Download 3D files of print-in-place objects without support Great trend in 3D printing for several years, "Print-in-Place" or printing in place no support has revolutionized 3D modeling for 3D printing. I use the 0. New Uploads. If the printer is connected to the Digital Factory, it is now possible to confirm the removal of a previous print job via the Digital Factory interface. I've printed a thousand of these and they all work fine and dandy. FotisMint Moon Dragon Bust. Save log files in paused state. Confirm print removal via Digital Factory. Surprise Egg 8 - Tiny Racecar Free.

I am final, I am sorry, but it at all does not approach me. Perhaps there are still variants?

Bravo, the ideal answer.