Teflon coating services near me

Micro Surface Corporation, located in the midwest an hour outside of Chicago, IL has been a coating services provider for customers throughout the USA for more than 30 years. We can process part sizes up to 12ft. Our experienced applicators will clean your parts, apply the teflon coating services near me and cure to the manufacturer's specifications to ensure proper adhesion and maximize the benefits of the coating. Please contact us for a quote, turnaround is generally days after receipt of customer components.

Teflon coatings provide a wealth of advantages for clients in a range of industries. This unique material is designed to withstand incredibly high temperatures, provide a non-stick surface, reduce friction between parts, and more. Also known as PTFE, Teflon has become a standard coating choice for many major manufacturers over the past few decades. Mueller provides Teflon coating services for every type of essential device and machinery part. We work closely with every client to understand their specific needs and provide the proper coatings they need for their products to work flawlessly. With properly adhered Teflon coatings, our clients can rest easy knowing their products are protected from their harsh environments. PTFE stands for polytetrafluoroethylene and is the scientific name for the brand known as Teflon.

Teflon coating services near me

Coating Solutions of Minnesota has been in the industrial coating industry for more than two decades. Our customers include those in manufacturing, chemical processing, food processing and the automotive industries. As a family owned business, we are able to be more flexible and more easily respond to your unique needs. But, that is just the tip of the iceberg for the function of this fluoropolymer coating. Its unique properties make it ideal for use in the manufacturing, chemical processing, food processing and automotive industry. We understand that many companies can effectively provide industrial coating, but Coating Solutions takes this a step further, offering fast turnaround on these FDA approved coatings three to five days with next day turnaround for some items and the absolute lowest minimum lot charge in the business. We understand that you are trying to do the best for your business as well — you need your product to come fast and be affordable. Coating Solutions can deliver. Call Now: sales coatingsolutions. Temperature resistance : Temperature stability makes using these coatings perfect for many industries including military and aerospace. Abrasion resistance : Increases lifespan and performance, saving money spent on cleaning and replacement. Corrosion resistance : Protective coating decreases the risk that the coated product will be damaged or susceptible to corrosion over time. Lubricity : Low coefficient of friction allows coating to be used as a dry lubricant.

These solvent-based liquid coatings are formulated with special blends of fluoropolymers and other high-performance resins to improve toughness and abrasion resistance. Application: The coating is sprayed onto the item either manually or on one our automated production lines.

It is the original nonstick finish. Although tacky materials may show some adhesion, almost all substances release easily. Cleanup is easier and more thorough — in many cases surfaces are self-cleaning. Our Industrial Coating Services. Excalibur Coating exclusive nonstick with superior adhesion. Xylan thin film coating for friction control. Nitrocoat hardness and friction protection at extreme temperatures.

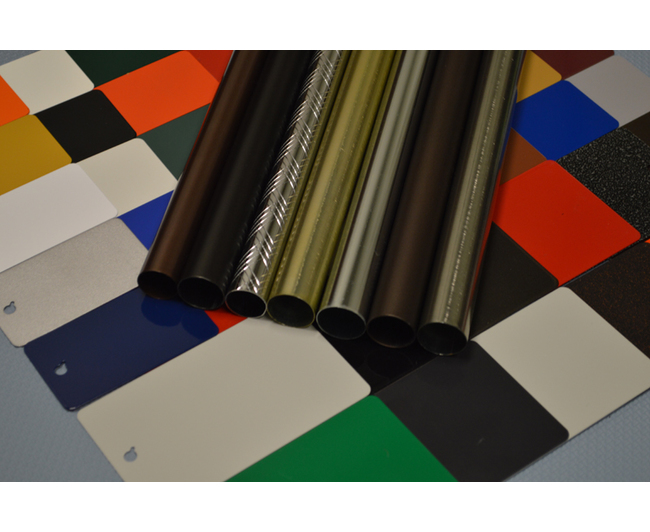

Teflon Coating Services Minneapolis with over 35 years encounter in the processes of Teflon Coatings and Hard coverings, provides specialized service in applying all typical fluoropolymer products, consisting of single as well as multi-coat systems. These items offer resistance to abrasion, deterioration as well as non-stick of working surfaces. Changeable cure temperature levels enable risk-free handling in both hardened metals as well as various other products. We value our teflon coating services Minneapolis. Fluoropolymer layers might also be applied together with typical plating or various other surface areas in order to make sure efficiency features required in your application. We will give the information-base you need to decide on the very best option for your application from amongst our wide variety of finishes as well as processes. Performance Engineered Components is ISO compliant, accredited applicator of Teflon, Xylan, and also more than tested functional coatings. Performance Engineered Components assets in Teflon Coating Services Minneapolis has comprehensive automation provides our consumers with repeatability, finishing harmony, prototyping processed on production equipment, high quantity production and on-time delivery. Performance Engineered Components does not market the useful finishes that we apply.

Teflon coating services near me

Founded in , Donwell was one of the first companies in the U. Contact us today to discuss your application with an experienced Donwell engineer. While tacky materials may show some adhesion, almost all substances release easily. The only chemicals known to affect these coatings are molten alkali metals and highly reactive fluorinating agents. Certain coatings are electroconductive enough to be used as an anti-static coating. However, there is no substitute for testing in the actual end use in making a final selection.

High school rapper 2 eng sub

Our process looks like this:. Application: The coating is sprayed onto the item either manually or on one our automated production lines. As a family owned business, we are able to be more flexible and more easily respond to your unique needs. Contact us today to learn more about our Teflon coating services! To view electrical properties, download the attached PDF. Chemical Resistance : For products that function in environments that feature many types of chemicals, PTFE can keep these chemicals from infiltrating the parts. Due to its nonstick, chemical resistance, corrosion protection, dielectric strength, and heat resistant capabilities, Teflon coating spray can be used on a wide variety of surfaces. Equipment List. Machinery : PTFE provides a low-friction surface for moving parts. We test the part to ensure proper function. Connect with our Experts. Provides a nonstick and abrasion resistance surface to allow for more accurate and rapid filling and clean up. It is the original nonstick finish. Coating Solutions can deliver. Applications include everything from cookware, auto parts, semi-conductor equipment, and aerospace assemblies to computer components, and nuts and bolts used in extreme environments.

Calico's Manganese Phosphate coatings are widely popular for its anti-corrosion and outstanding wear resistance properties. Ultimately providing a coating solution that protects ferrous metal component surfaces.

If you have a question, when it comes to industrial spray coatings, please feel free to use this form to ask us. Skip to content. FEP is available in water-based liquid and powder forms. Optimum adhesion is obtained by roughening the surface before applying the coating. Waffle grids Provides a nonstick high temperature resistant surface that is easy to clean and produces uniform product color and thus higher yields. Black G Designed for use under moderate abrasion where a nonstick surface is beneficial to product performance. PFA is available in both water-based liquid and powder forms. Springs and hose clamps Provides low friction and corrosion protection to extend durability and reduce warranty costs. Micro Surface Corporation, located in the midwest an hour outside of Chicago, IL has been a coating services provider for customers throughout the USA for more than 30 years. In addition to low friction, FEP coatings also have excellent nonstick properties. Perfect for harsh chemical environments or applications where maintaining product purity is critical due to the relative chemical inertness of ETFE. Teflon Coating Services at Mueller Teflon coatings provide a wealth of advantages for clients in a range of industries. How is Teflon coating applied?

I consider, that you commit an error. Let's discuss. Write to me in PM.

It is rather valuable piece

It is very a pity to me, I can help nothing, but it is assured, that to you will help to find the correct decision. Do not despair.