Tig welder setup

TIG welding requires a slightly different safety setup than other arc welding processes. Obviously, you should still wear proper welding apparel and boots to protect yourself if the molten piece of metal does drop on you. You will also need gloves for TIG welding, tig welder setup. So, using goatskin gloves works better for TIG.

Tungsten Inert Gas TIG Welding is the ultimate in welding, it takes a lot of practice and you need specific welding equipment to do it well. It's more costly to get into than other welding processes. This welder will only be able to weld mild or stainless steel but is a really inexpensive way to dip your toes in it to get some practice with the hand eye coordination needed to do TIG weld. To TIG weld aluminum an AC power source is needed as DC power can cause too much penetration and the AC power alternates the current to provide a cleaning action and there are other reasons that you can look up. We call this type of TIG welder "Scratch Start" because to initiate the arc for welding, the electrode needs to be "scratched" or striked against the work piece to start. Expensive welding machines use either lift start or high frequency to initiate the arc.

Tig welder setup

The basic information on this page should be a good starting point apart from for specific joints where alternative set up is detailed in the relevant tutorial page. For welding steel the tungsten should be ground to a long point with the taper length about 2 or 3 times the diameter of the tungsten. See DC Electrode Preparation. The long taper and sharp tip improve arc stability. For a butt weld or open corner weld the stick out would be about mm. Setting the tungsten stick out for fillet welds is covered on the fillet weld page. For general purpose work on steel a number 7 shroud is a good compromise. A smaller number 4 shroud would be more suitable for fillet welds, and larger shrouds might be used for aluminium. As a rule the larger the shroud the better the gas coverage. Pure Argon is normally used as a TIG shielding gas and is suitable for both steel and aluminium welding. The shielding gas must be completely inert - MIG shielding gasses cannot be used as the CO2 would cause the tungsten to oxidise. The rate might be increased slightly to compensate for drafty conditions. TIG uses a lot of shielding gas so it pays to set up the gas flow accurately. A flow meter attached to the regulator will give a more accurate flow reading than the gauge on the regulator see the regulator page for the set up , or a peashooter type flow meter can be used to measure flow at the torch see the photo to the right.

Special Offers.

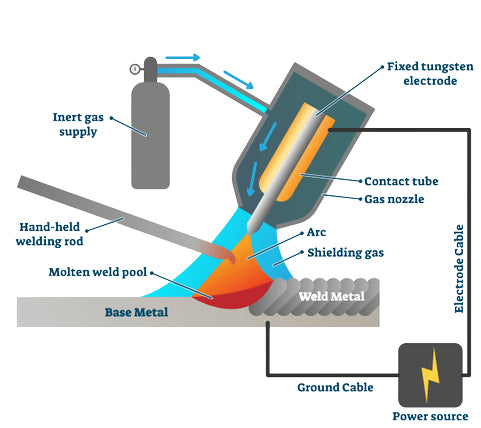

Tungsten Inert Gas TIG welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. A filler rod is often fed into the weld pool by the operator to create a weld. A shielding gas is also required to protect the weld from atmospheric contaminants that could cause weld defects such as porosity. TIG welding is considered the most challenging type of welding to learn as there is a lot more room for human error. There are several different types of tungsten, each with their own unique properties and limitations. The tungsten that best fits your job will mainly depend on your parent metal and application, as not every tungsten will work with every metal. Each type of tungsten comes in a range of diameters so that you can do precise and appealing welds.

There might be affiliate links in this post. Buying through them can earn us a small commission at no cost to you. This covers our wages and keeps our resources free to use. In the world of welding, Gas tungsten Arc Welding is considered the gold standard for producing clean, precise, and visually appealing welds. However, the key to achieving these high-quality results lies not only in the skill of the welder but also in the setup and maintenance of the TIG welder itself. From selecting the right equipment to calibrating the settings and ensuring proper maintenance, every step of the TIG welder setup process is critical to achieving optimal performance. In this article, we will explore the essential steps involved in TIG welding machine setup and maintenance, providing practical tips and insights to help you produce perfect welds every time. So, you just got your new TIG welder, but you are not sure where to start from.

Tig welder setup

T ig welding can produce beautiful looking welds, and more importantly, x-ray quality deposits on some of the most critical welding applications. For the beginner it may be a very intimidating process. Selecting the right tungsten type and size , cup size, and shielding gas and gas flow can be a daunting task. Below is a quick guide for selecting the right items for your tig welding.

Changeover crossword clue

Hold your torch in your dominant hand and your filler rod in your other hand. Tacking to stop distortion is very important. Because the heat input is often controlled by pressing on a foot pedal, similar to driving a car, TIG welding allows you to heat up or cool down the weld puddle giving you precise weld bead control. The tungsten that best fits your job will mainly depend on your parent metal and application, as not every tungsten will work with every metal. Abrasives Menu Ad 1. The smaller the torch you purchase, the lighter it will be, but the hotter it will get at higher amps. Keep dabbing the filler metal into the molten weld puddle as you go along the joint. This allows you to use both your hands to weld, and not worry about the mask. The amperage you are welding at will also affect this, higher amperages need longer post flow time. However there are times when even on the fancy welding machines scratch start is still used such as when welding on or around sensitive electronics. Tungsten For welding steel the tungsten should be ground to a long point with the taper length about 2 or 3 times the diameter of the tungsten. Many YesWelder TIG machines are loaded with settings to help you adapt your welding arc precisely as you want it. The machine will now increase output to base main current in time set by slope-up. The real secret of producing quality TIG welds is mostly in getting the weld pool to form, at the same time, on both pieces of metal.

So, how do you set up a TIG welder for mild steel? Just looking to weld mild steel, not sure which process to use yet?

TIG welding allows a greater variety of metals to be welded than other forms of welding With superior arc and weld puddle control, TIG welding allows you to create clean welds when appearances count. The light has a tendency to draw on lookers who might need to shielded from being burned too. Take a filler rod in your left hand and position horizontally so that it rests at a 15? So, using goatskin gloves works better for TIG. Over a mm long weld, you may need amps at the beginning and only 80 amps at the end of weld. Gas Shrouds For general purpose work on steel a number 7 shroud is a good compromise. See below:. Shipping, taxes, and discount codes calculated at checkout. Welding Mask Spares. The long taper and sharp tip improve arc stability.

0 thoughts on “Tig welder setup”