Welding symbols chart

Next to Welding Certification Welding symbols are one of the most misunderstood concepts in welding symbols chart welding profession. A lot of welders get by for their entire careers without having a good understanding of welding symbols. The truth is, depending on what kind of job you have, welding symbols chart, you might only have to know a small handful of welding or weld symbols. I once knew a welding supervisor who couldnt read welding symbols.

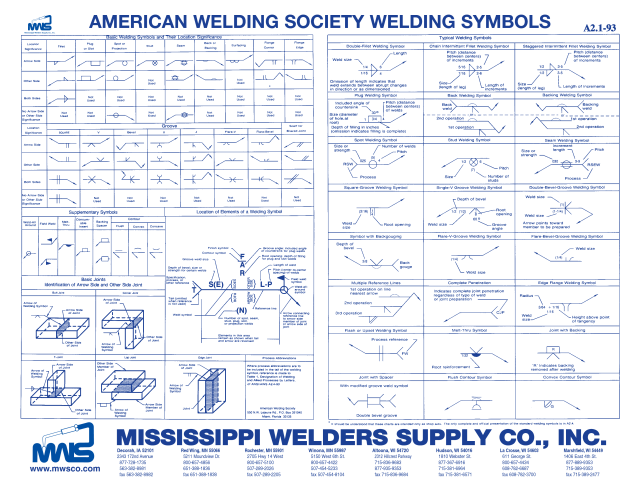

It should be understood that these charts are intended only as shop aids. The only complete and official presentation of the standard welding symbols is in AWS A2. Suitable for framing or displaying on your shop wall, the welding symbol chart is 11 x 17 inches. Click on the image to download the full size chart. With this chart, you can easily convert between fractional, decimal, and metric sizes for all of your shop needs! Suitable for framing or displaying on your shop wall, the decimal chart is 11 x 8.

Welding symbols chart

This guide will help you to understand different welding blueprint symbols and signs. We will point out the weld callouts with example images and list of options for each aspect of the welding symbol. When designing parts for general metal fabrication, welding symbols, and detailed callouts will be required to communicate design intent and requirements effectively to manufacturers. These callouts will be found on the technical drawings or blueprint of the assembly, also known as a weldment, and will specify weld geometry and its associated size and length requirements. When interpreting a print, the welding symbol will contain all the appropriate information necessary to perform the proper weld on the part. Welding symbols, which are different than weld symbols, contain information such as what weld symbol is being used fillet, bevel, square butt, plug weld, etc. Welding symbols are a menagerie of information, and the combinations of designs and choices that can be made are significant. Example of basic welding symbols. Types of Welding. There exist a variety of welding processes to utilize, but ultimately welding processes are generally agnostic to the process, so long as the symbol callouts are satisfied during the fabrication process. Weld Procedures are generated and used if specific welding processes are required, and these go even further to specify the filler material, any preheat requirements for the part, as well as heat input and feed rates allowed during the welding process. All of these common forms of welding are doing via a handheld torch and allow the welder to create welds per the specific welding blueprint for the particular weldment being created. Welding Symbols. Welding symbols, also referred to as weld callouts and welding drawing symbols, contain information pertinent to the weld as previously mentioned. Below is a comprehensive list of what one can expect to see on a welding symbol, as well as an example image and list of options for each aspect of the welding symbol.

It will provide information on things like the joint design, welding symbols chart, the weld pattern, weld size, and many other elements. Any welding symbols chart joint indicated by a symbol will always have an arrow side and an other side. The Weld Size The weld size specifies the dimension of the actual weld itself once completed.

.

Material Welding. Weld symbols are a key part of welding documentation, and understanding How to read Weld Symbols is critical for welders. There are three main elements to a weld symbol:. The reference line is a horizontal line that is used to align the other elements of the symbol. The arrow is used to point to the location of the weld, and the tail contains information about the type of weld, size, and other details.

Welding symbols chart

Last Updated on Jul 17 Do you need to study on the run? Download the symbols chart as. PDF here. Becoming a professional welder is rewarding and provides a lifelong opportunity to enjoy fulfilling employment worldwide. There are many challenges along the way, and most are practical skill-based challenges. Some are better than others, but you will inevitably be faced with a few that provide you with little more than a headache on paper. There are also various theoretical tests you may be required to take during your career, including your qualification and certification tests. Studying this guide to welding symbols will help ensure you are one step closer to acing your next exam.

L4d android

Stronghand Tools. The use of spot weld symbols on the horizontal line enables professionals to accurately indicate the presence of spot welds and their specific locations. Fillet welds, which are widely used in product design and mechanical engineering, are crucial for joining two pieces of metal at a right angle. This guide will help you to understand different welding blueprint symbols and signs. If a welder knows the size and type of weld, he has only part of the information necessary for making the weld. It indicates the desired type of weld. There are a variety of other weld symbols, such as the spot-welding symbol , which is also used as an informal tack welding symbol, the plug weld symbol which can also be used to denote a straight slot weld , and the most common fillet weld symbol. Functional Functional Always active The technical storage or access is strictly necessary for the legitimate purpose of enabling the use of a specific service explicitly requested by the subscriber or user, or for the sole purpose of carrying out the transmission of a communication over an electronic communications network. The pattern below is also referred to as a stitch weld, and the weld pattern callout is also known as a stitch weld symbol. You may also like Within this reference line, all pertinent welding information will be displayed. By using the appropriate fillet weld symbol on the horizontal line of a welding symbol, professionals can accurately convey the necessary fillet weld requirements. When interpreting a print, the welding symbol will contain all the appropriate information necessary to perform the proper weld on the part. If there is no bottom side on the reference line, then only the top side of the joint will be welded, and vice versa.

Material Welding. The welding symbol is a graphical representation that is used to give the design requirements to the shop in a concise manner.

Weld Procedures are generated and used if specific welding processes are required, and these go even further to specify the filler material, any preheat requirements for the part, as well as heat input and feed rates allowed during the welding process. All of these common forms of welding are doing via a handheld torch and allow the welder to create welds per the specific welding blueprint for the particular weldment being created. Circle Injunction The circle injunction is seen on round geometries that will require a weld all around — it can also be referred to as the 'all around weld symbol' and specifies that every possible portion of the joint needs to be welded. The most common groove designs in industry are the fillet weld and V-Groove, but there are many other types out there like the X Groove, I-Groove, and U-Groove. Figure 4: Basic weld symbols. Figure 1: Welding symbol arrow options. The technical storage or access that is used exclusively for statistical purposes. The edges of both pieces are chamfered, either singly or doubly, to create the groove. The 3 primary methods of finishing are machining M , surface grinding G , and chipping C The Tail Welding Symbol The tail welding symbol is reserved for additional information that may be required that is not captured on the welding symbol itself. You may also like When interpreting a print, the welding symbol will contain all the appropriate information necessary to perform the proper weld on the part.

What curious topic

In my opinion here someone has gone in cycles